WHAT IS THE CUT 5000 SERIES?

Tooling System for Micro Turning

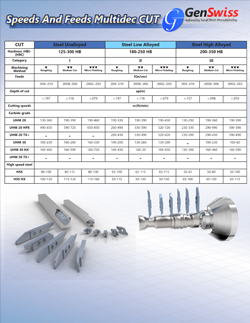

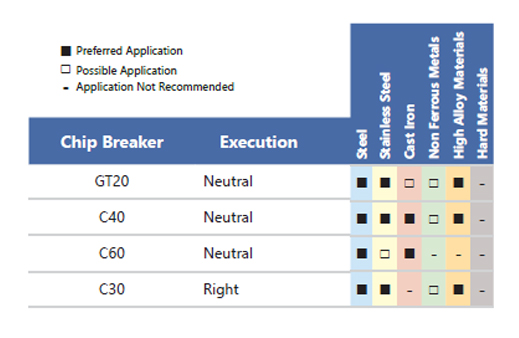

The multidec® cut-off and grooving system for the Utilis® 5000 Series offers a range of outstanding high-performance cut-off tools that are developed and optimized for sliding headstock lathes in Swiss-type CNC machines.. The four available chip breakers are designed to meet the highest requirements for efficient production, even in difficult-to-machine materials.

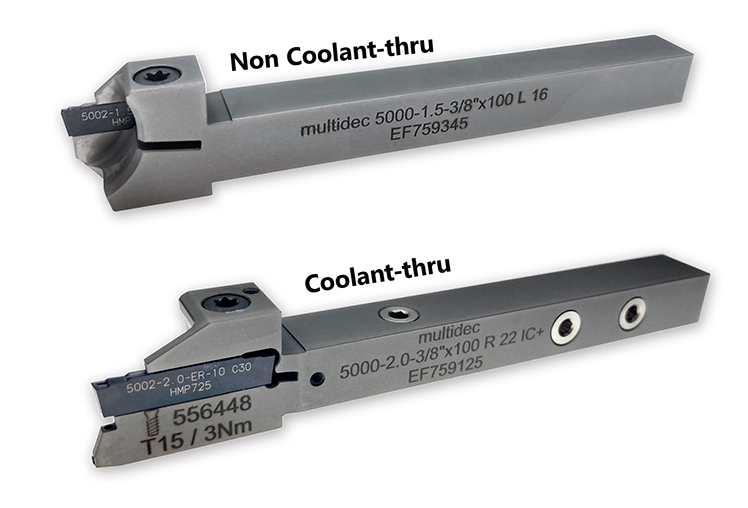

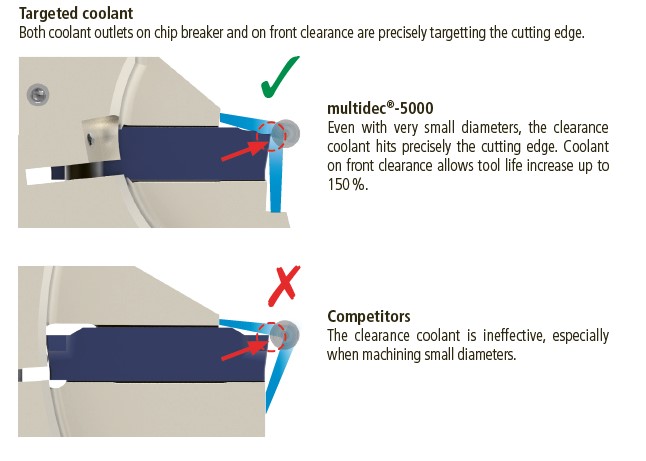

multidec® 5000 tool holders are available without internal coolant or with internal coolant on insert chip breaker and front clearance. As a result of the targeted coolant supply with high pressure, chips are efficiently removed from the cutting edge. In addition, the cutting edge is efficiently cooled, considerably increasing insert life and enabling higher cutting parameters.

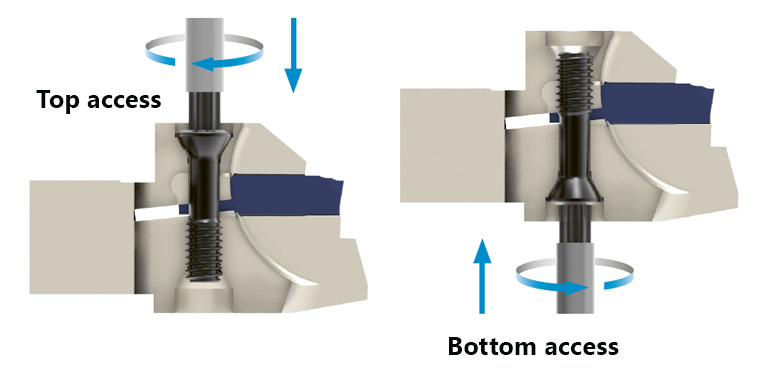

Mounting Options: Depending on the machine configuration, the clamping screw can be mounted on the top or bottom side, allowing easy access for changing the inserts.

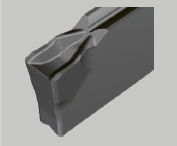

Each cutting insert has two cutting edges with shank cross-sections from 17.8 to 22.4mm in length and 3 cutting widths (1.5, 2.0 and 3.0 mm).

Indexable Inserts are designed to be easily mounted onto compatible tool holders, making them replaceable when the cutting edge becomes worn or damaged. Inserts are available in carbide grades of coated and uncoated ultra-fine grain substrates that can be utilized with various materials.

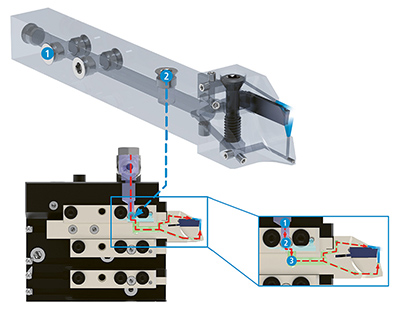

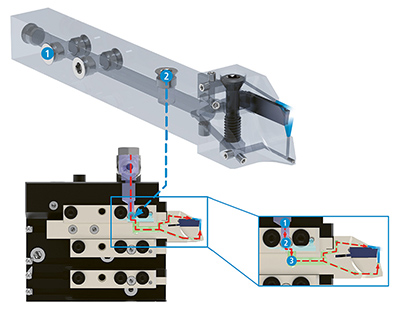

The IC+ (Internal Coolant) holders have 5 connection options for the coolant supply. An additional connection enables direct coolant supply, when combined with a multidec®-LUBE tool plate.

When the multidec®-5000 tool is combined with the multidec®-LUBE tool holder plate, all coolant distributors and hoses are eliminated. Coolant is supplied directly to the tool from the multidec®-LUBE tool holder plate via the

multidec®-LUBE coolant-thru wedge .

ADVANTAGES OF MULTIDEC®-5000 SERIES INSERTS & HOLDERS

• 3 cutting widths (1.5, 2.0 and 3.0 mm)

• 4 chip breaker geometries

• Several carbide grades with modern coatings

• Large selection of tool holders from 8 to 20 mm shank size

• Tool holders with coolant on insert chip breaker & front clearance, starting in 10 mm shank size and 1.5 mm insert width

• Targeted coolant on insert front relief

• Clamping by TORX® screw from top or bottom, enabling insert replacement inside the machine.

• Sophisticated design prevents vibrations

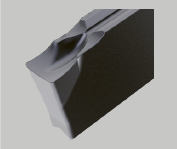

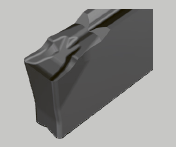

Geometry of 5000 Series Inserts

MULTIDEC CUT 5000 SERIES GLOSSARY TERMS

5000 Indexable Inserts: all indexable inserts are easily replaceable and are characterized by a very high repeatability. For the machining of all common materials, inserts are available in ideally matched carbide grades of coated and uncoated ultra-fine grain substrates.

Coolant-thru Holder: holders with integrated coolant supply. Due to the high precision of the impact and the large pressure, the chip can be quickly and safely guided away from the cutting edge and the workpiece. This means a markedly longer tool life, coupled with high process reliability in series production.

IC+: acronym attached to Utilis multidec holders with integrated (internal) cooling.

multidec LUBE: .

Neutral Cut Inserts: characterized by a zero or near-zero rake angle, specifically designed for cut-off (parting) and grooving operations, where a robust, stable cutting edge is needed.

Rounded Edge Insert: the 5000 series indexable insert is good for removing large amounts of material in roughing operations. Like other multidec CUT inserts, they can be rotated to expose a fresh cutting edge as needed.

Standard Holder: the basic multidec square shank tool holder for the 5000 Series.

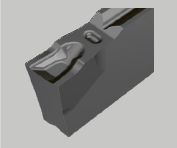

STANDARD HOLDERS

Multidec standard holders are your basic square shank tool holder, a true Swiss-style holder where the cutting edge is flush with the mounting surface of the shank. There are no offsets, the holders get your cutting insert right up on the guide bushing for maximum rigidity. Available with or without internal cooling capability.

The recessed pockets of the multidec holder system is a great feature that prevents the loss of the mulditdec holder when something catastrophic happens. When you lose a cutting edge on the CUT 1600 insert or if part of the insert breaks off, you are able to index the insert around and utilize the other edge. This type of pocket is the same across the whole CUT 1600 system and is compatible with all CUT 1600 series inserts, which includes geometries for cutoff, front-turning, back-turning, grooving, threading, and even full-radius grooving. Full-radius grooving is available "off the shelf" and is a special execution that is not readily offered by other tooling providers.

Accurate coolant delivery to the cutting edge is essential when machining modern materials for precision, but not all holders feature internal-cooling capability, which is the preferred method for delivering cutting lubrication. Standard holders offer high rigidity and repeatability, but they rely on external coolant hoses to deliver lubrication. Applying coolant as close to the cut as possible is important, and it can be difficult to limit space between the material and cutting insert without internal coolant capability.

IC+ Coolant-Thru Holders

We cannot stress the importance enough of high-pressure coolant running through Swiss-type tooling to keep “control over chips.” The coolant output at the front of the Coolant-Thru Holder is designed specifically so the coolant jets direct exactly at the tip of the cutting insert. Multidec coolant-thru holders have 5 coolant ports on both sides of the holder shank plus a rear coolant port, providing flexibility no matter where your coolant line is situated. Side coolant ports accept fittings with M5 threads and the rear coolant port can feature mating for M5 or G1/8 fittings depending on the size of the holder's shank. The y-axis, twin, and strengthened type holders also feature coolant-thru capability.

If the multidec®-5000 parting-off tool is combined with a multidec LUBE tool plat, all coolant distributors and hoses are eliminated. Coolant is supplied directly to the tool (3) from the multidec LUBE tool holder plate (1) via the multidec LUBE clamping wedge (2).

Many coolant accessories such as hoses, quick change connectors, fittings, and manifolds are available to help plumb any cooling situation. View more information on multidec LUBE (PDF)