WHAT IS THE CUT 1600 SYSTEM?

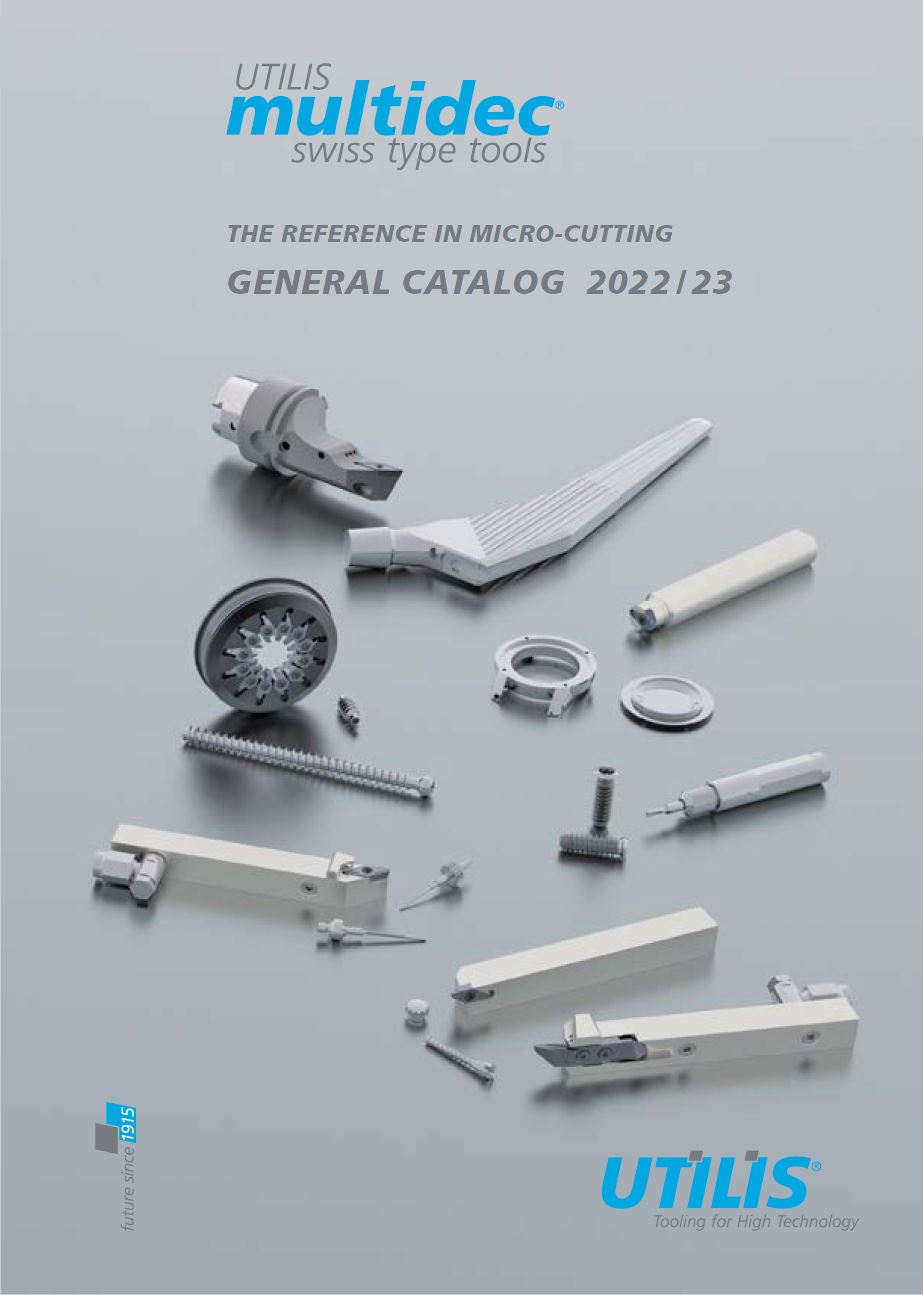

Tooling System for Micro Turning

The multidec® micro turning and cut-off system for the Utilis® CUT 1600 Series is suitable for Swiss type lathes up to a maximum of Ø10mm in bar diameter. This series includes a large selection of cutting geometries with assorted chip breakers, specifically designed for small parts manufacturing.

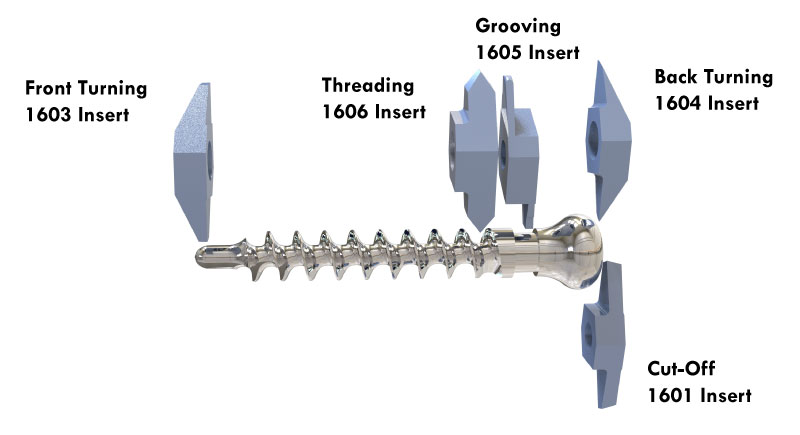

Universal 1600 Series Holders are built to fit all 1600 Cutting Inserts. The pocket is the same across the whole system and provides geometries for cut-off, front-turn, grooving and back-turning, threading and full radius.

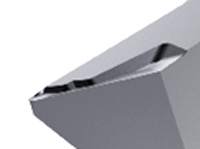

Each cutting insert has two cutting edges with shank cross-sections from 7 to 25mm in length. Full profile threading inserts begin at M 0.2 (0.06mm pitch) and grooving inserts’ width start from 0.05mm.

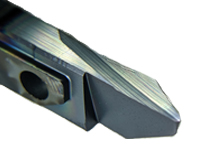

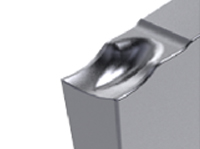

Indexable Inserts are designed to be easily mounted onto compatible tool holders, making them replaceable when the cutting edge becomes worn or damaged. Inserts are available in carbide grades of coated and uncoated ultra-fine grain substrates that can be utilized with various materials.

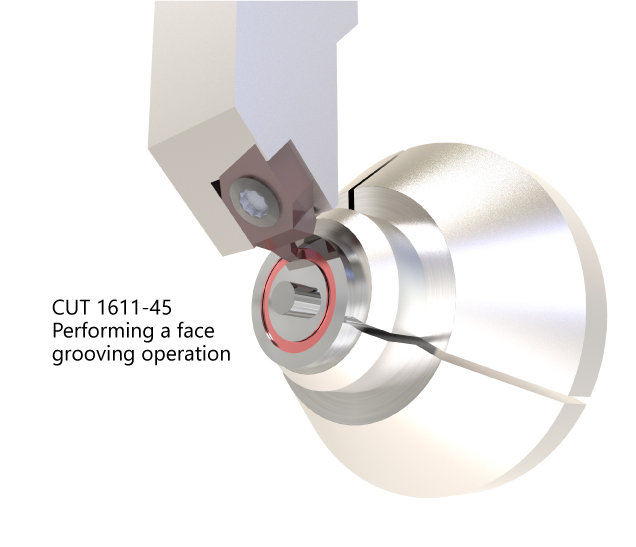

The tools can be combined with special ID working holders to handle axial (face) grooving and ID work on larger parts.

ADVANTAGES OF MULTIDEC®-CUT 1600 SERIES INSERTS & HOLDERS

• Indexable Inserts feature a Wide Variety of Chip Breaker Geometries

• All Inserts Fit the Same Holder

• Two Cutting Edges per Insert

• Cutting Edge Repeatable within .0004"

• Grooving Width up to 6mm

• Coolant Through Capability

• Improved Chip Control & Smaller Chip Volume

• Ideal for Micro Machining

VIDEOS

WHAT ARE THE BEST CASE USES FOR MULTIDEC®-CUT 1600 SERIES INSERTS & HOLDERS

The Multidec CUT 1600 series provides thin grooving and micro turning tools with inserts widths from the thickness of human hair (.00019") up to .108". This line is intended to meet the design and production requirements of micro medical devices, dental implants, micro electronic components and other parts featuring micro grooves.

Like other models in the Multidec line, these cutting tools come with toolholders that are designed to absorb cutting forces and protect cutting edges from shock and vibration. The inserts have two indexable cutting edges and are constructed of a micro-grained carbide grade that is balance for toughness and hardness properties. A varity of coating can be tailored for the tough workpiece materials typically machined in Swiss-type application, especially those smaller than 0.125 inch in diameter. Insert widths range from 0.0019 to 0.108 inch (0.05 mm to 2.75 mm) as standard products. Cutting edge repeatability is within 0.0004 inch. The sharp edge conditions and zero nose radius that come standard on these tools are ideal for micro machining applications.

The availability of these micro grooving tools makes it unnecessary for Swiss-machine users to grind their own tools or mofify existing tools. The handwork involved in producing or modifying tools in-house can be difficult and time-consuming, whereas the ready-to-use 1600 series tools offer an economical, more consistent alternative.

These tools are suitable for both prototype work and production jobs. They feature chipbreaker geometries to promote chip clearance, In addition to micro grooving, tools in this series can perform cut off, front-turning, back turning, profiling, micro-threading and other applications even on the smallest Swiss machines. Profile form tools to cut 0-80 pitch threads are also available. When paired with special ID toolholders, the inserts can perform axial grooving and ID work on large parts produced on larger machines as well.

Use of the Chip Breakers

| Designation | Operation |

|---|---|

| 1602 | Part Cut-Off |

| 1603 | Front Turn |

| 1603 GA | Front Turn, Face, Back Turn |

| 1603 GM | Front Turn, Face, Back Turn, Copy Turn |

| 1604 | Back Turn |

| 1604 V SP | Copy Turn (Front) |

| 1604 SP | Copy Turn (Back) |

| 1604 GB | Copy Turn (Back) |

| 1605 | Groove & Turn |

| 1606 | Thread |

| 1607 | Full Radius Groove |

| 1610 | Micro Groove |

| 1611 | Axial Groove |

| 1612 | Chamfering |

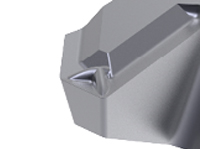

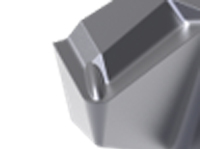

Geometry of 1600 Series Inserts

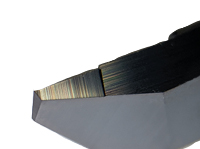

MULTIDEC® - CUT G-LINE INSERTS

With a focus on high productivity, process reliability, and the longest possible tool life, perfect chip control becomes a central issue in all modern production. These requirements are often difficult to fulfill with traditional ground chip breakers because of insufficient chip break and removal.

In comparison to traditional grinding technologies, new manufacturing technologies have increased the degree of design freedom tremendously, providing the ability to generate any three-dimensional shape. The new G-Line from multidec has adopted the use of this new free-form design technology, resulting in well thought-out chip breaking geometries that are fitted to the well-tried multidec -CUT 1600 and CUT 3000 series of turning inserts, providing maximum performance.

Freeform-modeled chip breakers achieve significant improvements in a wide range of materials when compared to ground chip breakers. This advantage is particularly evident with difficult to machine materials such as super-alloys. In addition to significantly improved chip control, multidec G-Line inserts can achieve up to 30% higher cutting values and up to 50% longer tool life.

ADVANTAGES OF MULTIDEC®-CUT, G-LINE INSERTS

• Improved Chip Control

• Better Cutting Values

• Longer Tool Life

• Smaller Chip Volume

• Better Process Reliability

• Wear-resistant and Tough Carbide Substrate with Two Heavy-duty Coatings

• Sharp and Rounded Cutting Edges

• Can be used on all Multidec-CUT 1600 and Multidec-CUT 3000 Holders

Execution of holder/insert

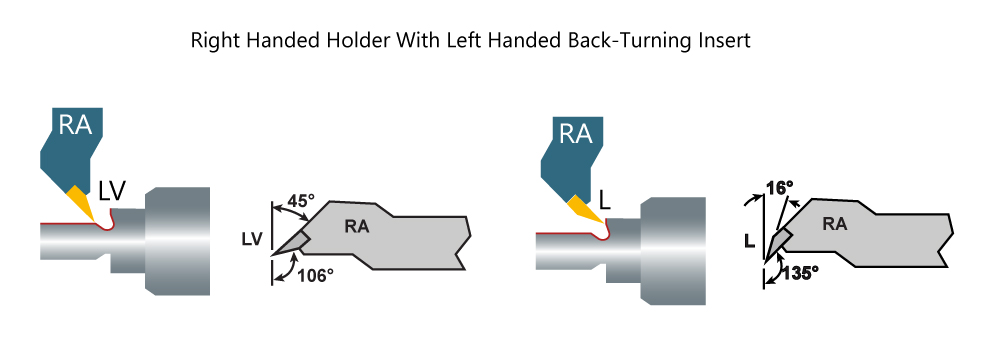

The side on which the insert is located determines whether it is a "left" or "right-hand" holder. For this purpose the holder is viewed with the insert pointing towards the observer.

The right-hand version of the tools is usually shown. (Exceptions are possible). For more information or to order G-Line products, please call 1-413-562-4800 or email [email protected]

MULTIDEC CUT 1600 SERIES GLOSSARY TERMS

45 Degree Holder: used for face grooving and making undercut features. The insert cutting edge of the holder engages the work piece at a 45 degree angle compared to a standard holder.

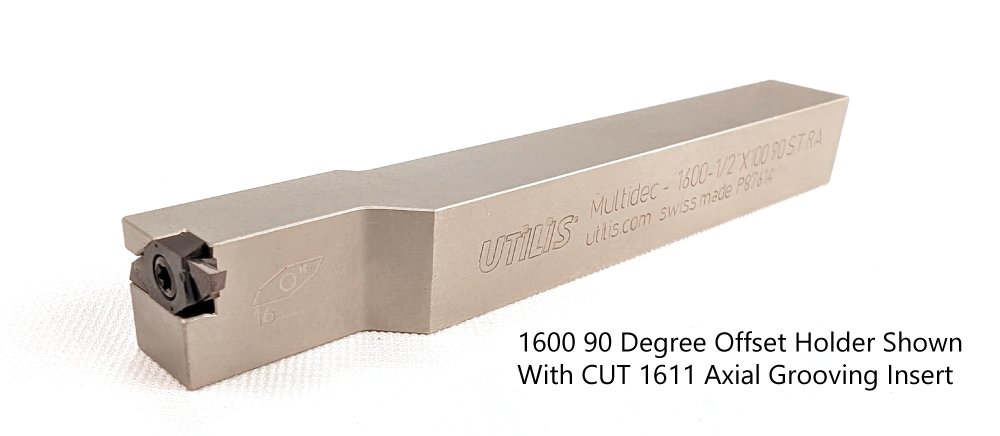

90 Degree Holder: used for face grooving and internal features. The insert cutting edge of the holder engages the work piece at a 90 degree angle compared to a standard holder.

Coolant-thru Holder: holders with integrated coolant supply. Due to the high precision of the impact and the large pressure, the chip can be quickly and safely guided away from the cutting edge and the workpiece. This means a markedly longer tool life, coupled with high process reliability in series production.

G-Line Inserts: freeform-modeled chip breakers achieve significant improvements in a wide range of materials in comparison to ground ones.

Gold Line Holder: provides a newly designed cooling system making it possible to double the lifetime of the cutting edges as well as increase the cutting parameters without having to accept higher wear.

IC: acronym attached to Utilis multidec holders with integrated (internal) cooling.

Indexable Inserts: all indexable inserts are easily replaceable and are characterized by a very high repeatability. For the machining of all common materials, inserts are available in ideally matched carbide grades of coated and uncoated ultra-fine grain substrates.

multidec-CUT: the multidec range of indexable insert tools from Utilis, offer cutting-inserts and holders for internal and external turning, on swiss-type automatic lathes.

multidec Short Holder: shorter holder that enable the use of multidec inserts on commonly available quick change tooling systems. All multidec Short holders feature internal cooling.

Standard Holder: the basic multidec square shank tool holder for the CUT 3000 Series.

Strengthened Holder: enables the use of the CUT 1600 series inserts on larger Swiss-style machines such as 32mm machines.

Twin Holder: mounts two inserts at the same time. Various combinations are available and offer the user a lot of flexibility. Twin holders are available with shank cross-sections from 8 to 20 mm in both non-coolant-thru or coolant-thru.

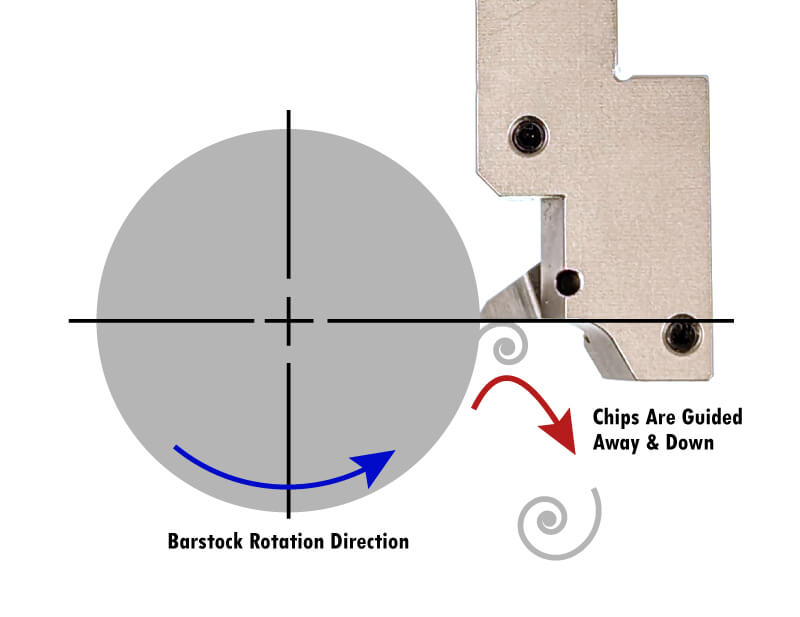

Y-axis Holder: helps with chip control problems that can occur when turning long-chipping materials. The cutting edge is offest by 90° compared to the standard holder, which causes the chip to fall onto the bed of the machine. With the Y-axis holder, you will never get another "bird's nest" of chips on the cutting edge.

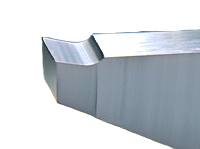

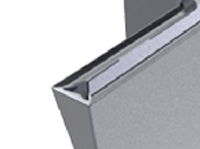

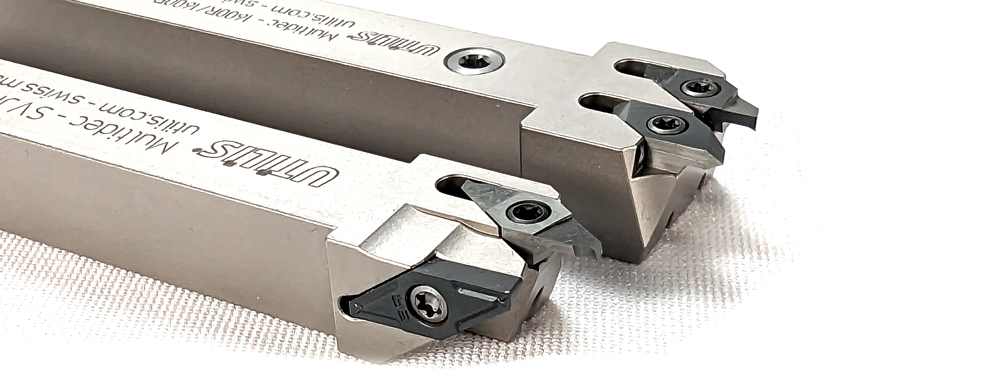

1600 STANDARD HOLDERS

Multidec standard holders are your basic square shank tool holder, a true Swiss-style holder where the cutting edge is flush with the mounting surface of the shank. There are no offsets, the holders get your cutting insert right up on the guide bushing for maximum rigidity. Available with or without internal cooling capability.

The recessed pockets of the multidec holder system is a great feature that prevents the loss of the mulditdec holder when something catastrophic happens. When you lose a cutting edge on the CUT 1600 insert or if part of the insert breaks off, you are able to index the insert around and utilize the other edge. This type of pocket is the same across the whole CUT 1600 system and is compatible with all CUT 1600 series inserts, which includes geometries for cutoff, front-turning, back-turning, grooving, threading, and even full-radius grooving. Full-radius grooving is available "off the shelf" and is a special execution that is not readily offered by other tooling providers.

Accurate coolant delivery to the cutting edge is essential when machining modern materials for precision, but not all holders feature internal-cooling capability, which is the preferred method for delivering cutting lubrication. Standard holders offer high rigidity and repeatability, but they rely on external coolant hoses to deliver lubrication. Applying coolant as close to the cut as possible is important, and it can be difficult to limit space between the material and cutting insert without internal coolant capability.

1600 COOLANT-THRU HOLDERS

We cannot stress the importance enough of high-pressure coolant running through Swiss-type tooling to keep “control over chips.” The coolant output at the front of the Coolant-Thru Holder is designed specifically so the coolant jets direct exactly at the tip of the cutting insert. Multidec coolant-thru holders have 5 coolant ports on both sides of the holder shank plus a rear coolant port, providing flexibility no matter where your coolant line is situated. Side coolant ports accept fittings with M5 threads and the rear coolant port can feature mating for M5 or G1/8 fittings depending on the size of the holder's shank. The y-axis, twin, and strengthened type holders also feature coolant-thru capability.

Many coolant accessories such as hoses, quick change connectors, fittings, and manifolds are available to help plumb any cooling situation. View more information on multidec LUBE (PDF)

1600 TWIN HOLDERS

The twin holder is meant for work within the 8-20mm range and is available with or without internal cooling capability. This holder doubles the number of tools while allowing operators to both perform two duel or separate operations. Twin holders are phenomenal for operations requiring multiple inserts or where you don't have too many turning positions and that extra position is needed. Multidec CUT 1600 series twin holders allow you to put two 1600 series inserts on the same holder. Some holders enable the ability to hold a 1600 series insert and a multidec ISO series insert. For instance, a twin holder can hold both a CUT series 1605 grooving insert and a CUT series 1606 threading insert or a CUT series 1603 front-turning insert and an ISO TOP type insert. ISO TOP cutting inserts such as a VPGT come featured with TOP wiping geometry that enables a very smooth finish and at higher speeds & feeds.

When adding two inserts of the same cutting operation, twin holders will save you some time by reducing machine downtime due to tool changes on a long production. Rather than worrying about a failing insert, the job can be programmed to switch to the second insert, enabling you to run an additional full run on that second insert. No more worrying about lights-out manufacturing. The only thing to keep in mind is that the close pocket position on the holder limits the type of operations that can be achieved.

1600 Y-AXIS HOLDERS

Multidec Y-axis holders are perfect for long-chipping materials, allowing for better chip control. The 90° inverted design allows chips to fall onto the bed of the machine. If you are removing a significant amount of material for an operation, such as back-turning or front-turning, and you are having trouble controlling chip wrap, this is an option for you.

The Y-axis holders are also coolant-thru capable, featuring coolant jets aimed precisely at the cutting edge, with or without high pressure. The holder can be used for just about any kind of turning operation.

1600 STRENGTHENED HOLDERS

Multidec CUT 1600 series strengthened holders feature larger shanks, allowing fitment into 32mm machines where machining very fine features on some bigger Swiss-style workpieces is required. This holder allows larger machines to take advantage of the CUT 1600 series line of micro machining inserts. All strengthened holders offer coolant-thru capability accepting M5 threaded coolant fittings on the sides and G1/8 fittings on the rear.

1600 45 DEGREE HOLDERS

Multidec CUT 1600 45 degree holders provide a way torigidly hold a CUT 1600 series insert while performing axial or radial undercuts with a CUT 1604 back-turning insert or face grooving features with a CUT 1611-45 insert.

The 1600 45 degree holder below is shown with a CUT 1611-45 grooving insert. The cutting edge on the insert itself is designed with a 45 degree angle so that when combined with this holder, face grooving operations can be performed. Each of these inserts are designed to cut at a minimum diameter where the groove must be created. When this combination of insert and holder are used, pair them with opposite executions. A right handed holder will use a left handed insert.

Even though multidec 1600 90 degree holders enable face grooving operations, the CUT 1600 45 degree holders and 1611-45 inserts are designed with a greater relief, allowing for much smaller minimum radius sizes down to 0.8mm.

When paired with a CUT 1604 back-turning insert, the 1600 45 degree holder can perform undercut features. With this combination of insert and holder, a right-handed holder must be used with a left-handed insert and visa versa. Changing the direction of cut, an LV insert vs an L insert, will change the type of cut that can be made.

1600 90 DEGREE HOLDERS (AXIAL AND INTERNAL FEATURES)

Multidec CUT 1600 90 ST offset holders provide axial grooving capabilities and work in tangent with multidec CUT 1611 axial grooving inserts. The offset holder geometry enables face grooving operations with minimum radius sizes ranging from 7 to 18mm. These holders require an opposite handed insert. (i.e.: a right-handed holder uses a left-handed insert)

Internal features can be machined using the standard CUT 1600 90 ST holder in tangent with 1600 series inserts. A minimum hole diameter of 21mm is required to fit this holder. These holders require an opposite handed insert. (i.e.: a right-handed holder uses a left-handed insert)