WHAT ARE TI-LOCS?

Swiss Clamp System

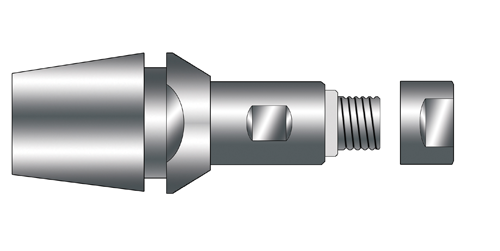

The Ti-Loc® SwissClamp System is a taper-integrated micro tooling system designed to work with collets or tool holders that match the ER collet system (DIN6499). The Ti-Loc directly mounts into any ER Taper Live or Static Tool Position. It comes standard with ER8, ER11, ER16, ER20, ER25 taper arbors that serve as their own collet, eliminating the need for two-piece arbor system.

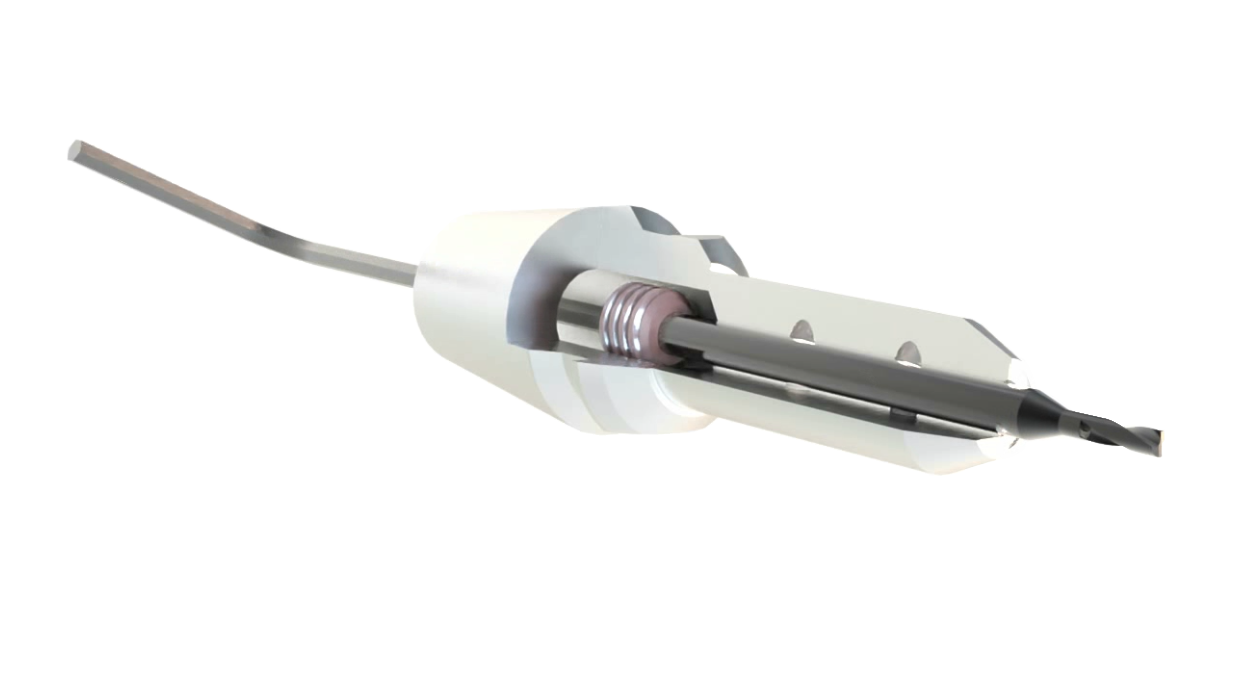

Designed for both sawing and milling, repeatable positioning is a given as well as increased rigidity. For example, the endmill extension holder permits extended reach in tight spaces without having to hang a small diameter endmill out far, thereby preventing chatter or tool life issues due to lack of rigidity. Overall, the design concept simplifies the tooling through less components and eliminates inaccuracies caused by "tolerance stacking".

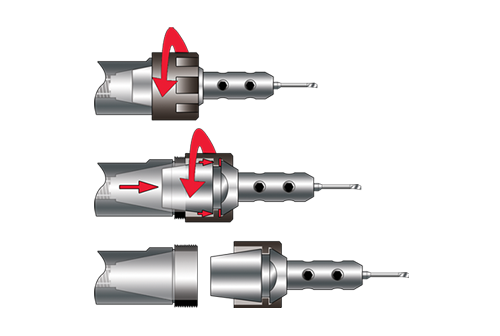

The tool holder bore is held to an exacting tolerance and has a nearly hydraulic fit with the shank of the micro end-mill when quality micro tools are used. Installation or changing the Ti-Loc Tool Holder is fast and easy, simply twist and snap the micro tools into any ER clamping nut. Ti-Loc tapers come precision ground for improved accuracy and feature a stop screw for repeatable tool positioning.

VIDEOS

Micro End Mill Extensions

• Advanced rigidity and accuracy in micro applications

• Ideal for tool extensions

• Can be used in any machine that has ER collet live tooling

• One piece design is less expensive and more cost effective

• Maximum T.I.R. of <.0002"

• Aids in clearing the guide bushing

• Enables quick change of tooling

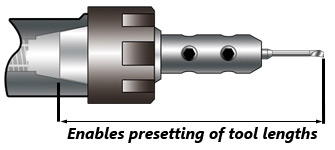

• Allows for pre-setting of tool lengths

• Solves deflection and chatter issues

• Eliminates inaccuracies caused by "tolerance stacking"

• Precision ground ER taper on ER8-ER25 sizes

• Coolant-thru capability available on ER16

• On-demand manufacturing available call 1-413-562-4800

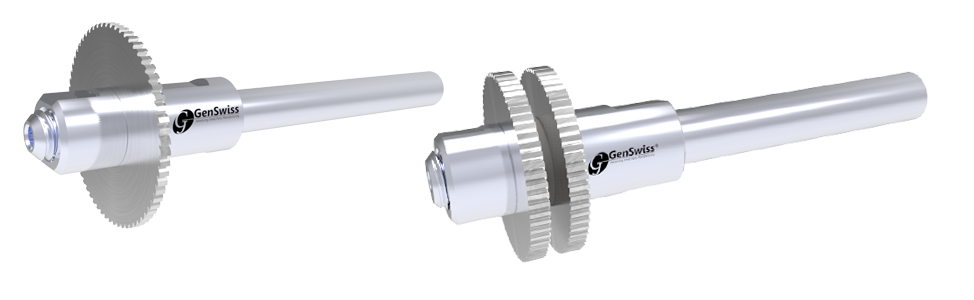

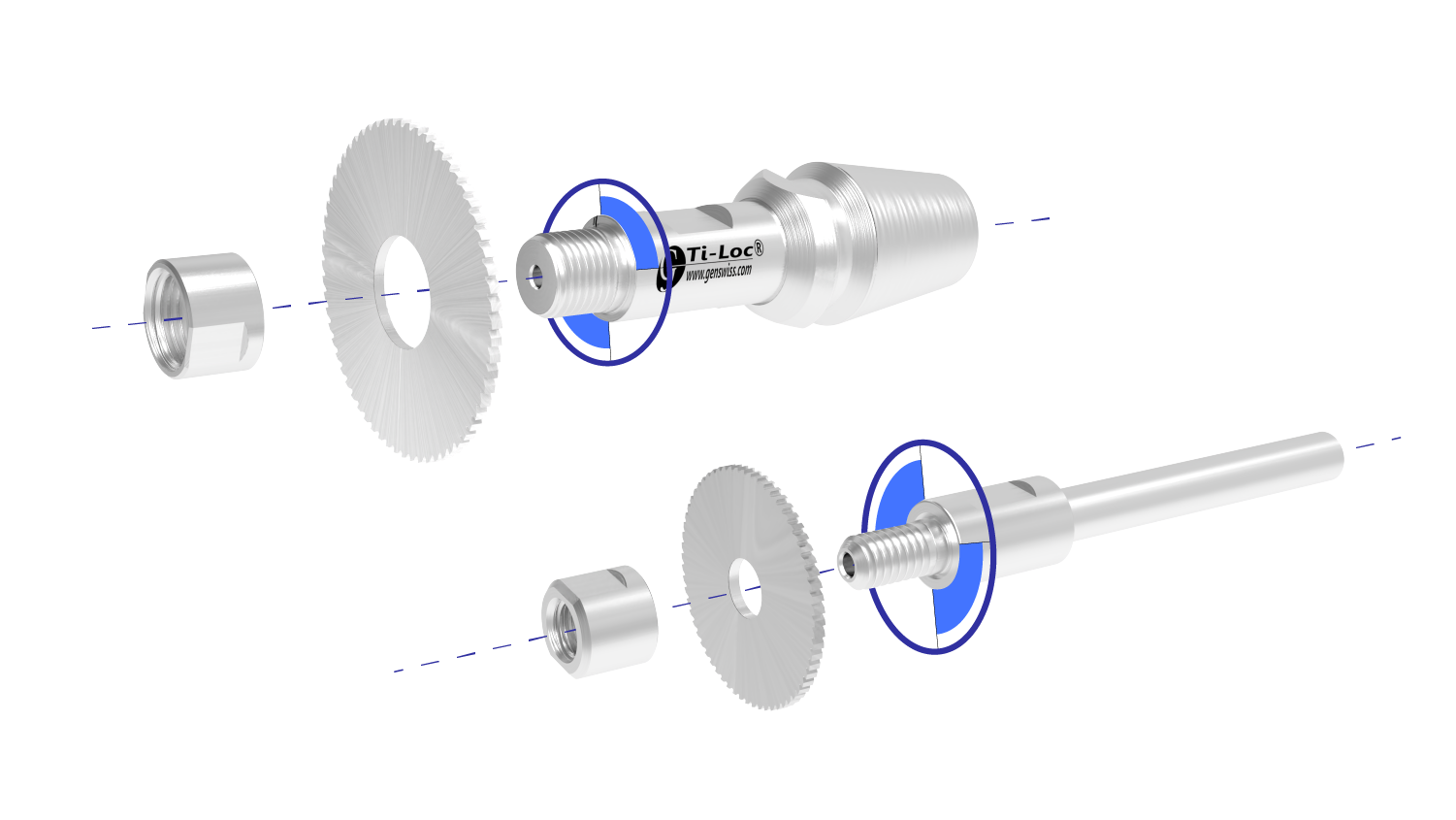

Why Choose Ti-Loc Saw Arbors

• High accuracy, general purpose slitting/sawing applications

• ID grooving operations

• Length, less vibration

• TIR held to <.0002" or better guaranteed

• Precision ground ER taper & Saw Mounting Journal

• Repeatable positioning of Saw Journal

• Integrated ER taper for maximum rigidity

• Directly mounts to any ER taper live or static tool position

• Enables quick change of tooling

• Snap groove fits into most standard ER clamping nuts

• Large variety of solid carbide slotting saws down to .008" in thickness (Metric OD x ID combinations)

• Custom Arbors available for order call 1-413-562-4800

WHAT ARE THE BEST CASE USES FOR TI-LOC TOOL HOLDERS

Ti-Loc SwissClamp Slitting and Milling Tool Holders are commonly used in rotary cutting a variety of materials, including metal, plastic, wood, and composites. They are used primarily in manufacturing aerospace and automotive, medical and dental.

Enables Quick Change of tooling into fixed locations. No special holding nut is required. The quick change is accomplished by loosening the clamping nut allowing the tool holder to break from the locking taper of the spindle or sleeve. They are internally stopped to adjust positioning of the shank. Operators can preset offline for use as quick change or swap out while installed in multiple positions on live tools.

TI-LOC GLOSSARY TERMS

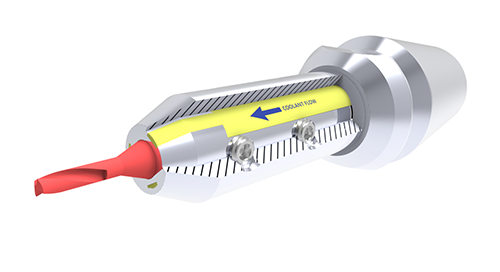

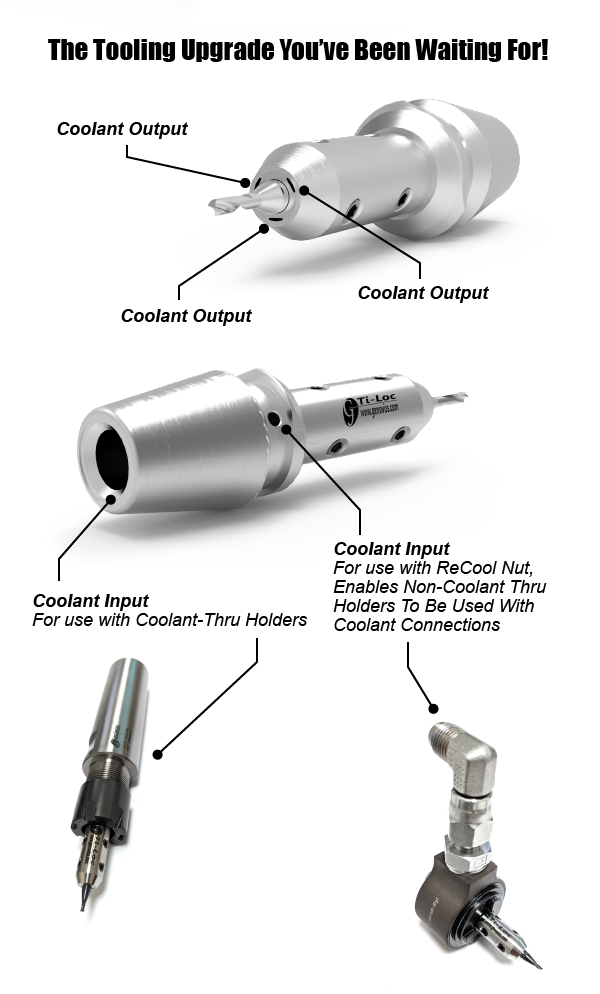

Coolant-thru: the Ti-Loc ER-16 Coolant-thru versions provide the added benefit of optimum edge control and chip evacuation and can be paired with standard coolant-thru collet sleeves as well as coolant-thru live tooling. The ER-16 tool is connected to a properly equipped spindle and toolholder, the coolant flows through the drills internal ducts and out of the tools tip.

ER Collets (DIN 6499): developed and patented by Rego-Fix in 1973, ER Collets (DIN 6499) is the most widely used clamping system in the world. Standard sizes available on the Ti-Loc products are ER-8, ER-11, ER-16, ER-20, ER-25. The "ER" comes from an existent "E" collet which Rego-Fix modified and appended "R" for "Rego-Fix". The number is the cavity opening diameter in millimeters, the outside collet diameter. ER collets contract over a range of 1mm and are available in 1mm or 0.5mm steps, so a range of ER collets can hold any cylindrical shank, metric or imperial.

Endmill: rotating tool that is used to remove material from a workpiece in milling applications, such as profile milling, tracer milling, face milling and plunging. Ti-Loc Endmills are made of high-speed steel (HSS) or carbide and come in a variety of shapes and sizes.

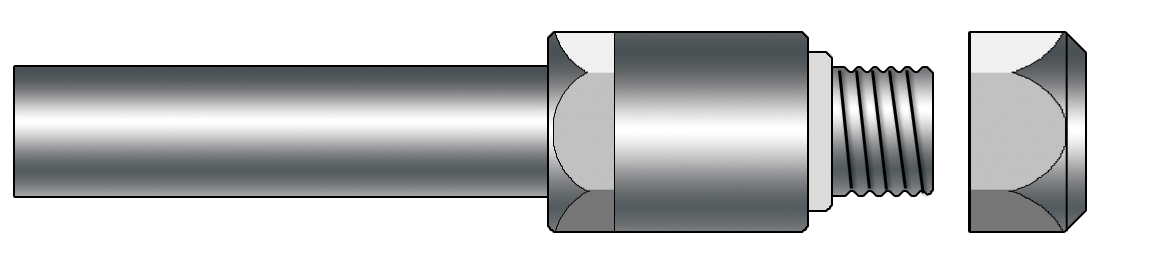

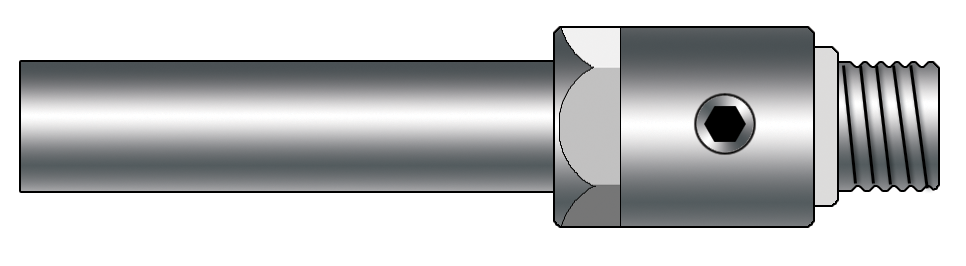

Internal Stop: Ti-Locs have an adjustable positive stop on the inside where the shank of the tool inserted and the ID here is a very tight tolerance, making the fit of the tool very stable. Internal stop can be adjusted from both ends of the holder using a standard hex key.

Micro End Mill Extensions: available to hold 3mm-8mm and 1/16 inch-5/8 inch shanks.

On-Demand Manufacturing: Ti-Loc products are built to order and often customized to individual specifications.

Quick Change: accomplished by loosening the clamping nut allowing the tool holder to break from the locking taper of the spindle or sleeve.

Rigidity: the primary point of contact to the machine spindle is the taper of the toolholder. The surface area contact between the two will set precedence for all machining ability.

Slitting Saws: very fine toothed saws used to cut narrow through slits or slots in material or for performing undercut operations. They come in a variety of sizes and are typically made from either HSS or Carbide.

Tolerance: typical Total Indicator Reading (TIR) is held to 0.0002" or better.

TI-LOC COOLANT THRU

Ti-Loc Mill Extensions and Saw Arbors (ER16) integrate coolant-thru capability. In addition, the ER16 taper arbors serve as their own collet, eliminating the need of a two piece arbor system. With the increased usage of micro tooling operating at higher speeds in more compact tooling zones, these micro tool holder offerings helps solve the need for more efficient machining operations while extending tool life.

Our variants are designed to provide the added benefits of optimum edge control and chip evacuation and can be paired with standard coolant-through collet sleeves as well as coolant-through live tooling. For live tools unequipped with coolant-through capability, a coolant-through nut such as REGO FIX's ReCool nut can be used to deliver high pressure coolant to each of the Ti-Loc's coolant delivery ports surrounding the micro tool. (NOTE: Ti-Loc® Tooling is designed to fit best with REGO-FIX® Hi-Q® nuts. May not be compatible with other brands).

ADVANTAGES OF TI-LOC COOLANT THRU

• Precision Ground Er16 Taper

• 3.0mm & .125inch Tool Shank Diameters

• Maintains Exceptional TIR at extended length

• Allows Micro Tools to Clear the Guide Bushing

• Works with Coolant-Thru Holders, Live Spindles & Recool Nuts

TI-LOC SAW ARBORS WITH INTEGRATED ER TAPER

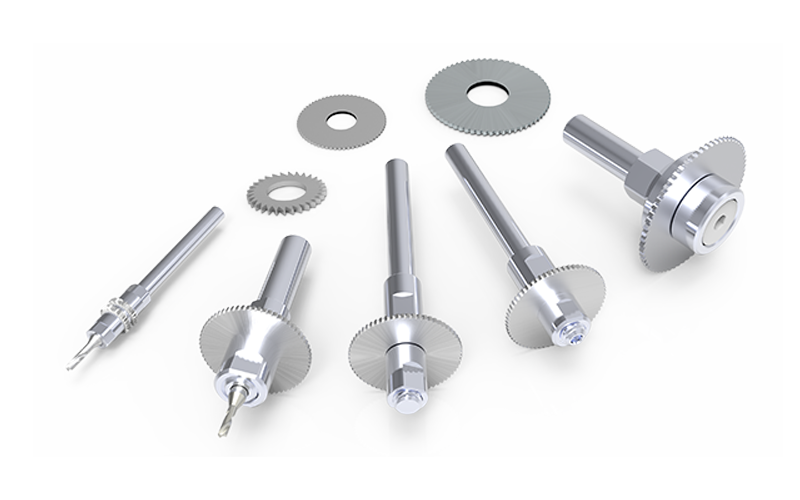

GenSwiss' Ti-Loc saw arbors can be used in any machine that has ER collet live tooling. The tool directly mounts into any ER Taper Live or Static Tool Position. Simply insert the Ti-Loc holder into most ER nuts and twist to align the locking cam profile just as you would any ER collet. It comes standard with ER11, ER16 and ER20 taper arbors that serve as their own collet, eliminating the need for two-piece arbor system. GenSwiss stocks a large variety of Swiss-made solid carbide slotting saws down to .008" in thickness in a variety of Metric OD x ID combinations. View Slitting Saw Speeds & Feeds

This single piece design adds rigidity of setup and improves total indicated runout (TIR). In fact, it reduces tolerance "stacking" to an incredible low TIR of 0.002 or better. Less expensive and more cost effective than most comparable two-piece arbor systems with a recommended maximum saw thickness of approximately 0.080". Custom arbors are available. Call to inquire 1-413-562-4800 (USA) and order today.

Precision Saw Arbors - 5025 Series (SAP) (SAP-E Extended Journal)

Our most popular style of slitting saw arbor is available in guaranteed TIR grade SAP (border .0002” TIR) and the extended journal version SAPE. When ULTRA Precision is required the SAP guide is suggested as they are held to stringent quality standards required by discerning Swiss-type machinists.

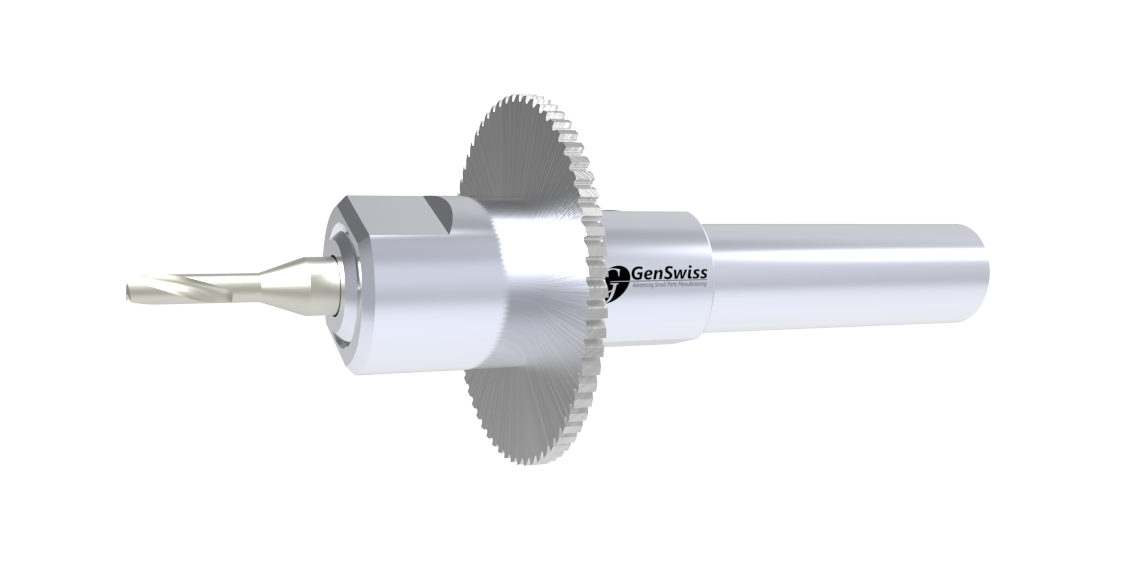

Combination Saw Arbors - 5015 Series

GenSwiss combination arbors are made from pre hardened material and exemplify what it means to be called "Swiss Precision". The addition of the combined mill or center drill provides additional tool capacity and setup flexibility.

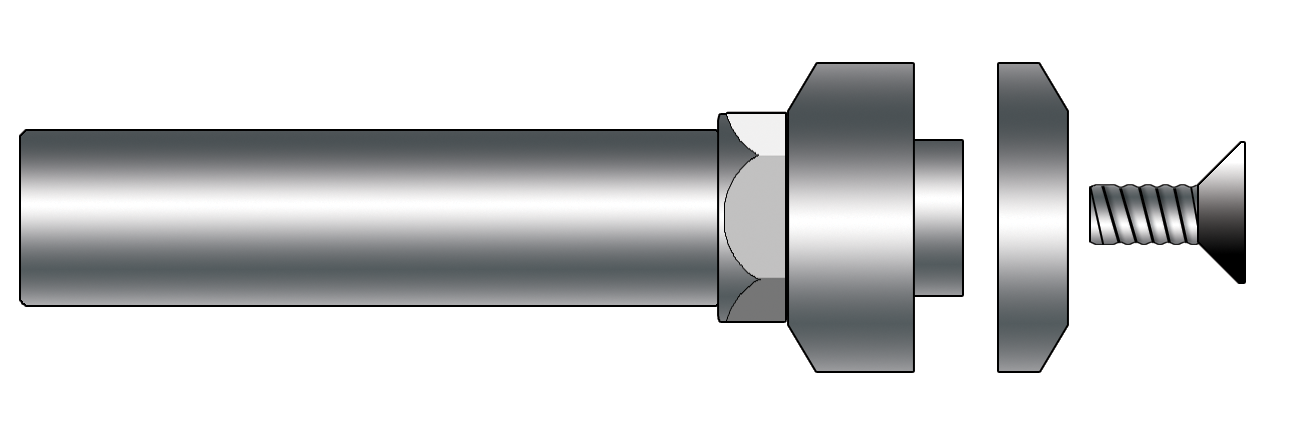

Flange Saw Arbors - 5020 (SAF)

These metric flanged saw arbors provide maximum saw balance and stability with the flange mount design. The unique design applies pressure to the outward edge of the flange ensuring the greatest gripping power at the outer most edge to prevent slipping. Uses countersunk screw and flange washer to apply holding force. Measured TIR is less than .0002”.

Ti-Loc Saw Arbors

• Taper-integrated small tooling provides unparalleled ease of use for advanced productivity

• Maintains exceptional TIR at extended length

• Solves deflection and chatter issues

• TIR less than .0002 inches at full extension

Custom Slitting Saw Arbors

GenSwiss has the capability to assist with the engineering and the manufacturing of special gang slotting arbors that also feature the option of holding an end mill, spot drill or other small round shank rotary tool.

Features we provide include:

• Spacers for gang slotting with multiple blades

• Custom hub widths (L1 dim.) for oversize blade thicknesses

• Optional shank sizes for special applications

• Live Tools custom made to fit

View Micro Tool Saw Arbors & Slitting Saws Product Knowledge Page

|

Ti-Loc® is a patented design of GenSwiss® Signature Series Line of Premium Products made in the USA. Standard and custom orders are available. We strive to deliver products which meet or exceed customer expectations, providing a reliable service with application solutions. Contact us for more information 1-413-562-4800 |