BORING

WHAT IS BORING?

In CNC Swiss machining, boring is a type of internal diameter (ID) operation used to enlarge an existing hole to a precise diameter or to machine an internal surface with different shapes. Swiss machines are versatile and can perform various types of boring operations, which are generally categorized by the specific objective and the type of tooling used.

Depending on the required hole size and specifications, boring is the ideal method for machining holes of different precision grades, diameters, and positional restrictions. In fact, it’s more suitable than drilling for creating holes of large sizes because of its improved accuracy.

WHAT ARE THE BEST OPTIONS FOR BORING IN SWISS MACHINING?

• Signature Series Mini Boring System

VIDEOS

TOOLING FOR BORING

multidec® micro bore

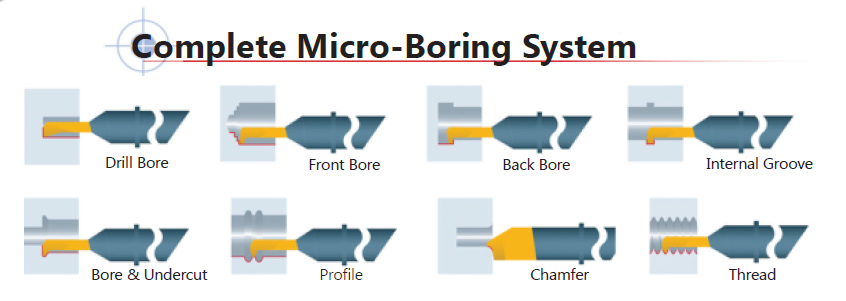

The multidec®- Micro-Bore system provides high quality inner diameter (ID) machining operations including chamfering, spotting, threading, I.D. grooving and internal profiling with a variety of standard cutting edge diameters from 0.5 to 8 mm.

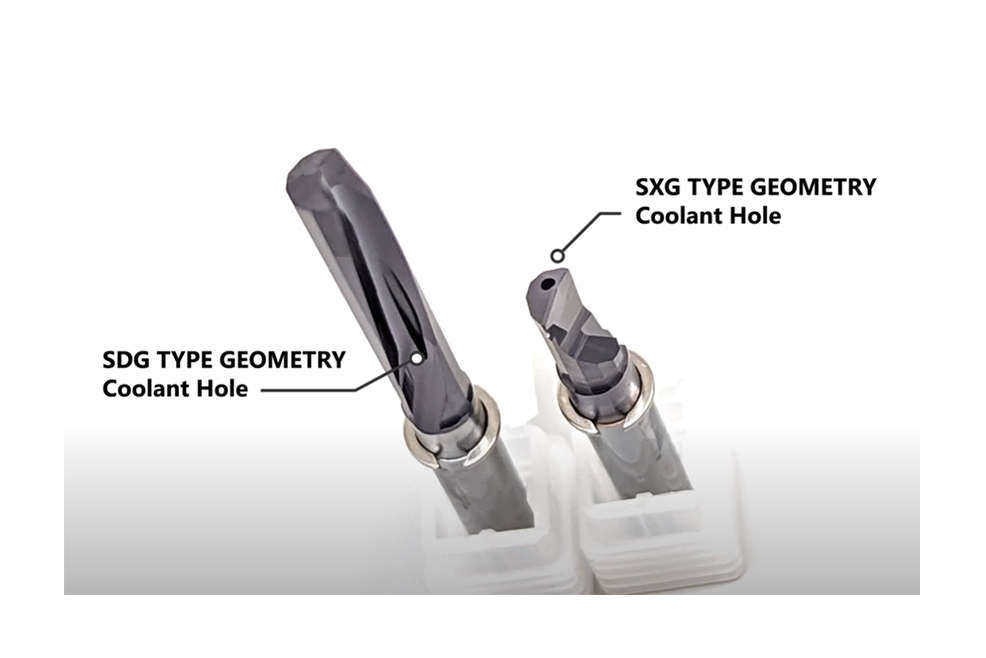

The solid carbide micro boring bars are available in 4 mm, 6 mm and 8 mm performing in a multitude of geometries.

In addition, every boring bar and holder has coolant-thru capability. Some of the geometries contain two variants depending on where you want the coolant to be so you can have it on the front where the coolant port is going in with the cut, there is also an inverted one where the coolant comes around the back so if you have a scenario where you are going into a blind hole and the coolant is blowing in there but the chip is on the other side of the boring tool the coolant will flow around the edge and then blow the chip back out.

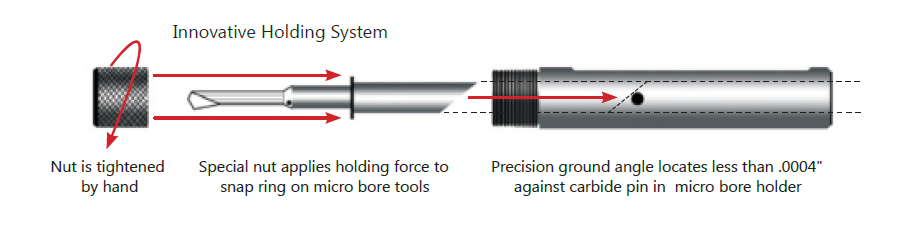

Locating micro boring bars in the holder is made simple and easy for quick micro-boring bar changes. The uniquely designed boring bar incorporates an angled back that locates the bar less than .0004" against a positive location pin in the bar holder. By simply hand tightening a fine pitch threaded knurled nut applies the force needed against boring bar snap ring. Great feature for machinists that have little experience and saves time on quick-change.

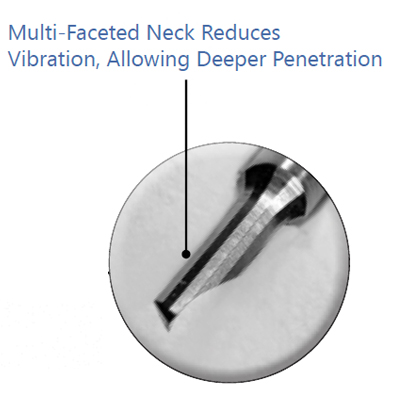

No wrenches are needed, significantly limiting micro-boring bar breakage from slipping wrenches in tight tooling areas. The boring bar necks feature multi-faceted surface for reduced harmonics, resulting in improved surface finishes and longer insert life.

This is a complete working system ideal for small parts precision machining, especially medial applications.

ADVANTAGES OF MULTIDEC®-MICRO BORE

• Tough carbide grades available in coated or uncoated

• Standard Grade is UHM20 HX

• Precision ground angle locates less than .0004" against carbide pin in micro bore holders

• Multi-faceted neck reduces vibration, allowing deeper penetration

• Numerous cutting geometries

• Coolant-thru capability

• Complete Micro Bore System

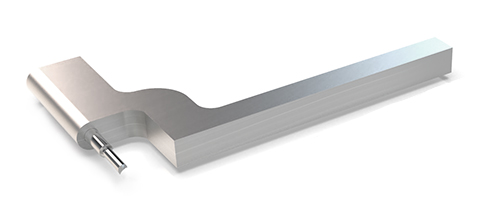

AKR Dogleg Holder

• Low profile

• Interference free in most Swiss machines

• Ideal for small ID spotting, drilling and boring

• Available in 8 mm, 10 mm, 12 mm, 16 mm and .500 shank sizes

• Reduction Sleeves to convert inches to metric shanks or increase diameter from 12 to 16 mm or 16 to 22 mm

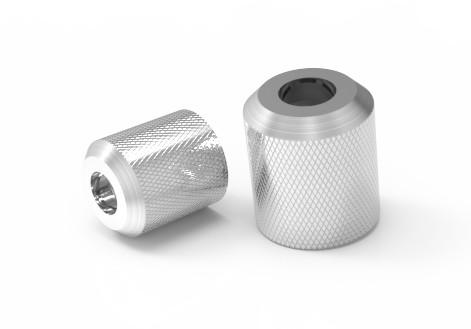

Spare Clamping Nuts

• 4 mm, 6 mm, 8 mm to accommodate holders

• Special knurled texture to help grip considering oil surfaces inside the machines

• Sold as part of the microbore holder and available for order separately

Coolant Fittings

• Use with SDA Holders to allow HP Coolant

• SDA Holders come with 1/8" or M5 threads

• Available with 90 degree elbow between threads

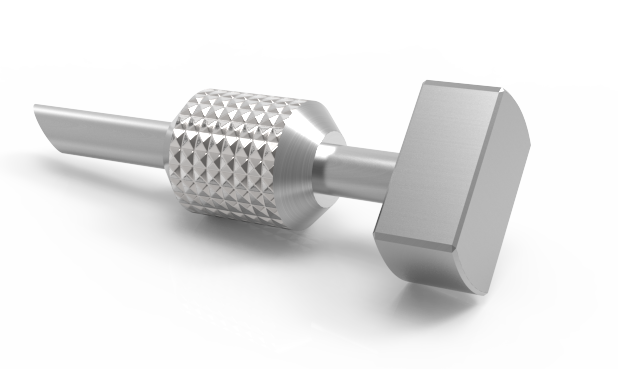

Setup & Location Tool Alignment Device

• Tool used inside the bore of the SDA Holder

• Helps indicate the long flat to find the 0 in one axis (X and Y) then divide the thickness of the long flats by 2 to find 0 in the other axis (X or Y)

• Available in 4 mm, 6 mm and 8 mm shank diameter

Retaining Rings

• Spare retaining rings available in 4 mm, 6 mm and 8 mm sizes to fit micro bore shanks

• Retaining ring prevents the bore bar from coming out of the holder

Signature Series Mini Boring Bar System

The Signature Series Mini Boring System offers a cost-effective line of solid carbide coolant-thru tool shanks ranging from 4 mm–16 mm with coated and non-coated indexable ISO inserts down to minimum bore diameter .189 inch (4.8 mm) made for internal diameter (ID) profiling. View more information on the Mini Boring System (PDF)

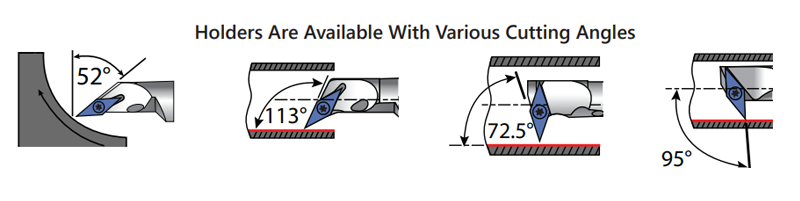

Holders are available with various cutting angles, 52 degrees, 113 degrees, 72.5 degrees and 95 degrees.

Mounting the ISO Anti-Vibration damped boring bars on a machine is easily done with Coolant-thru Boring (CTB) Bushings. GenSwiss produces the tool bushings in-house to fit the most common outer diameter (OD) sizes on Swiss machines with custom-made sizes made available on request.

Ideal for boring almost every material type, with the exception of high-temp alloys, the solid carbide tool shanks combined with the steel coolant-thru bushings provide maximum rigidity in small diameters.

Coolant Kits

Maintain long tool life with high pressure chip evacuation and coolant delivery with GenSwiss' coolant kit and accessories. Just thread a coolant kit fitting right into the bushing and then run a high-pressure hose to plumb the mini boring bar with coolant.

Maintain long tool life with high pressure chip evacuation and coolant delivery with GenSwiss' coolant kit and accessories. Just thread a coolant kit fitting right into the bushing and then run a high-pressure hose to plumb the mini boring bar with coolant.

GenSwiss' high-quality line of Signature Series tooling is engineered specifically to advance productivity in Swiss-style machining.

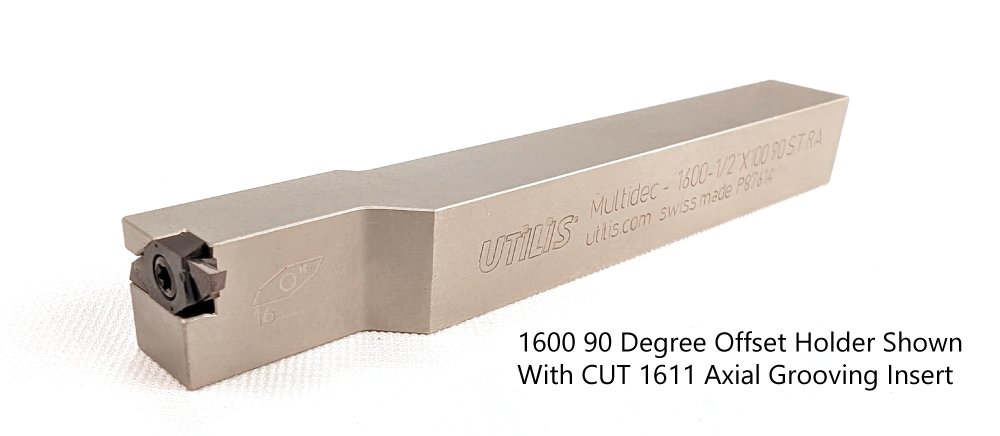

1600 90 DEGREE HOLDERS (AXIAL AND INTERNAL FEATURES)

multidec CUT 1600 90 ST offset holders provide axial grooving capabilities and work in tangent with multidec CUT 1611 axial grooving inserts. The offset holder geometry enables face grooving operations with minimum radius sizes ranging from 7 to 18mm. These holders require an opposite handed insert. (i.e.: a right-handed holder uses a left-handed insert)

Internal features can be machined using the standard CUT 1600 90 ST holder in tangent with 1600 series inserts. A minimum hole diameter of 21mm is required to fit this holder. These holders require an opposite handed insert. (i.e.: a right-handed holder uses a left-handed insert)

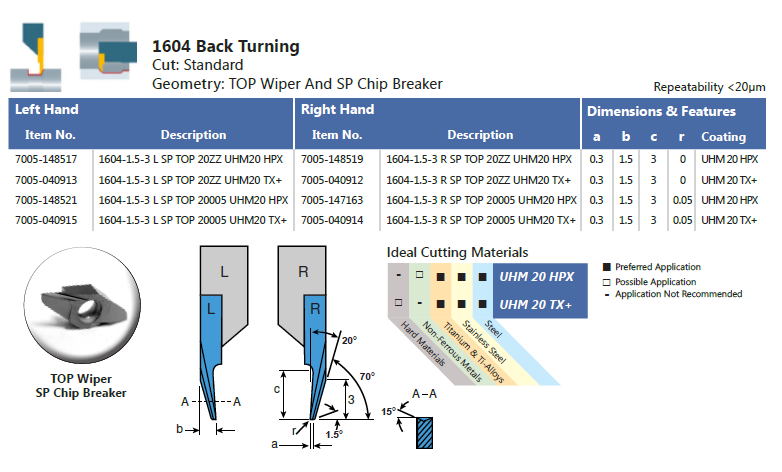

The Type SP 1604 Profile Turning Chip Breaker is a good choice for doing internal copy, profiling, generating radi, internal grooving internal threading, again it pushes the bigger ID work on a Swiss machine, but there's times when people are doing work that large.

With the precision and long tool life provided by multidec® 1600 series inserts and holders, machine shops will save significantly more money while also producing highly accurate parts that will pass any high industry standard.

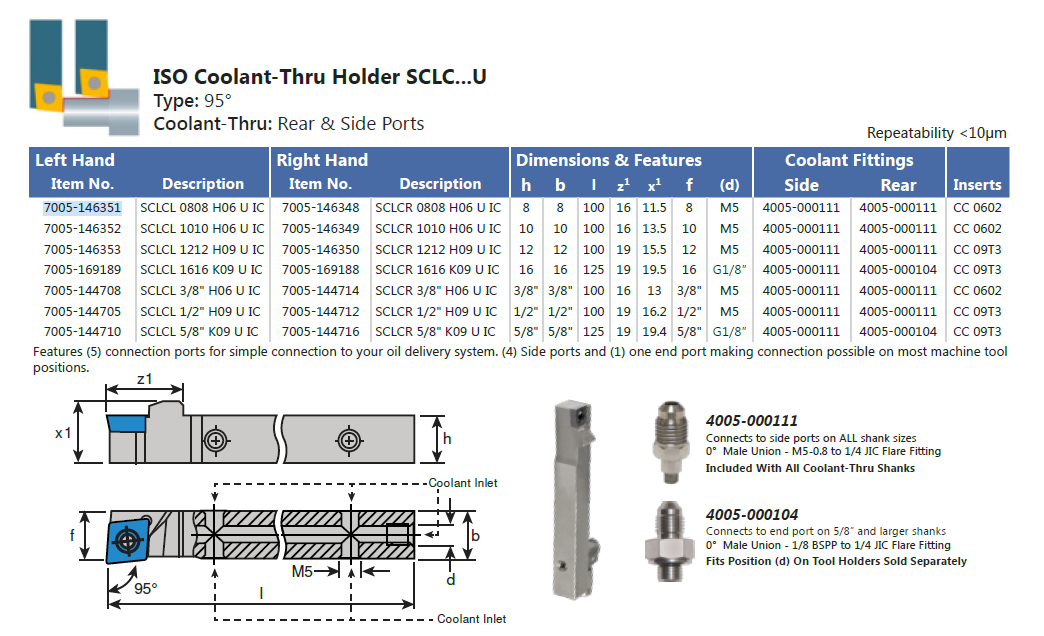

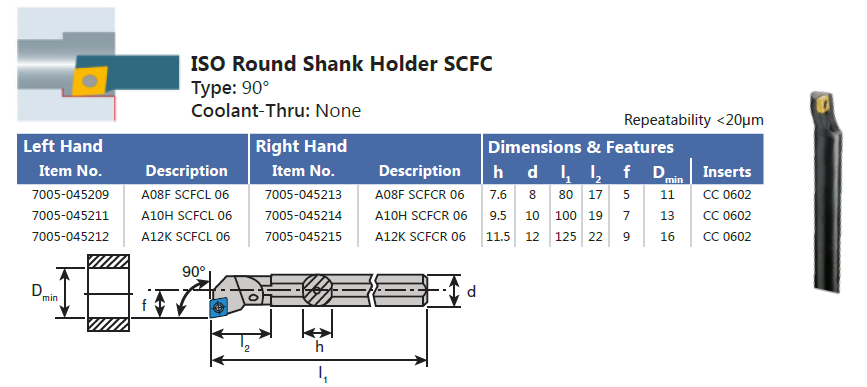

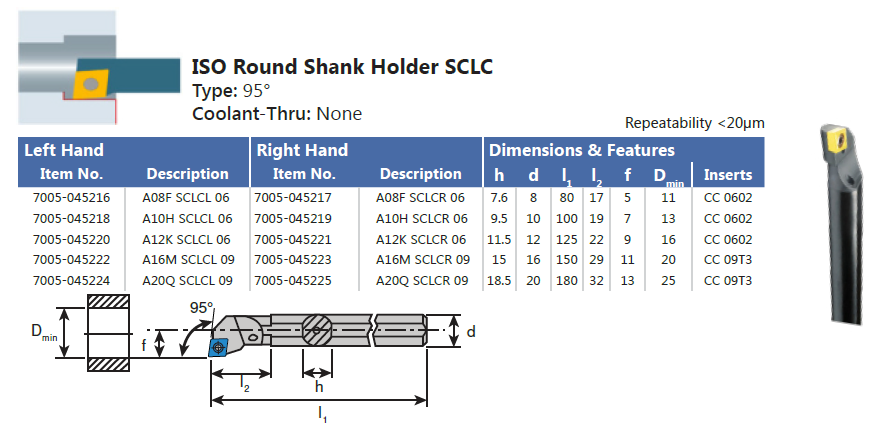

ISO Holders

multidec-ISO tool holder shanks are specifically designed for Swiss-Type machines, retaining positioning close to the guide bushing, ensuring rigidity and accuracy. Fits ISO CC 80° inserts. The Coolant-Thru Holder features (5) five connection ports for simple connection to your oil delivery system (4) four side ports and (1) one end port making connection possible on most machine tool positions.

Boring Bar Adapter

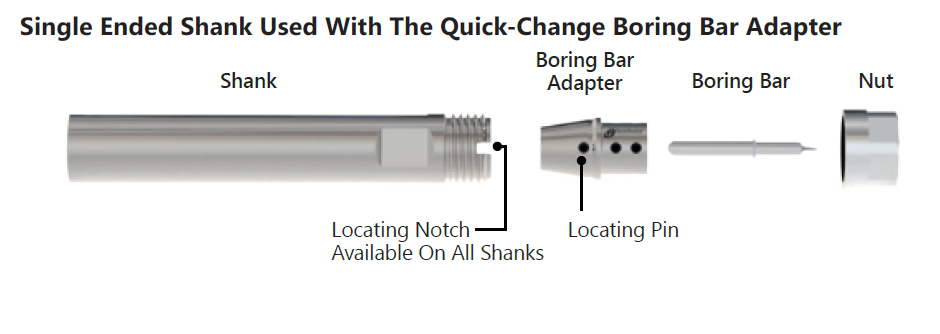

The GenQuick tooling system helps new users as well as seasoned veterans achieve faster setups and tool changes through the use of tool holder adaptors and quick-change modules that can be preset and are based on the ER standard tool holding system.

These collet sleeves are cost effective solutions to tool holding and are available in a variety of both inch and metric sized shank diameters, and feature a solid shank for rigidity and a side coolant port for connection to a high-pressure coolant delivery system. Every unit has a notched collet taper for easy tool orientation when combined with quick-change boring bar adapters.

CONCLUSION

CNC boring is a high-precision manufacturing step that follows after a hole has been rough-drilled. It’s used to make parts with very accurate hole diameters that can be repeated hundreds of times. Boring is the foundation of precision engineering.

If you want to see if CNC boring is right for your next application, contact our technical experts at GenSwiss and get a free quote.

Need to solve your precision hole machining challenges and achieve strict geometric tolerances and surface finish requirements?

Please send us your engineering drawings and material specifications.

We will leverage our practical machining expertise to deliver a customized boring process design and provide technical support.

We look forward to partnering with you to ensure the precision and long-term reliability of your critical components.