Turning Tools

|

|

MULTIDEC® 5000 Series

|

|

|

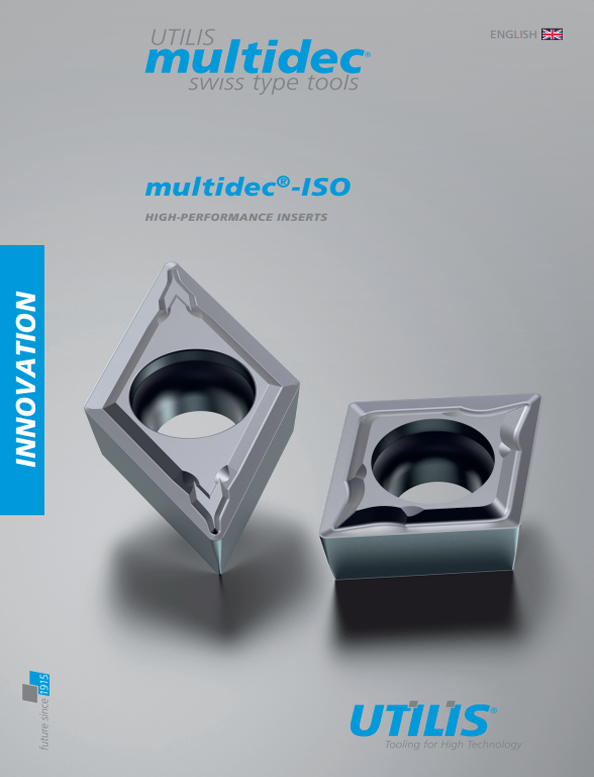

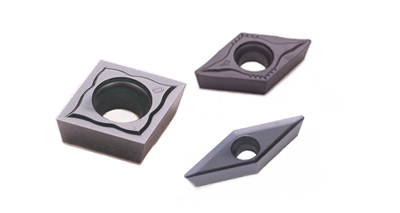

MULTIDEC® ISO Inserts

|

|

|

MULTIDEC® IC PLUS TOOL HOLDER

|

View PDF View PDF

|

MULTIDEC® LUBE

|

View PDF View PDF

|

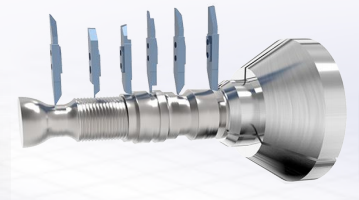

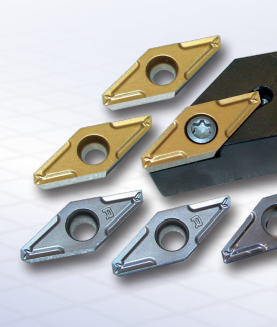

MULTIDEC® CUT G-Line Inserts

|

View PDF View PDF

|

MULTIDEC® TWIN Insert Holders

|

View PDF View PDF

|

Speeds and Feeds Multidec CUT Series

|

View PDF View PDF

|

Speeds and Feeds Multidec ISO Series

|

View PDF View PDF

|

Speeds and Feeds Multidec TOP Series

|