LIVE TOOL & SPINDLE REPAIR

GenSwiss® was founded on Live Tools more than 20 years ago. We have the largest selection of Live Tools available and we have been selling Live Tools longer than any other company in the Swiss-Machine Industry.

WHAT IS LIVE TOOLING?

Live Tooling uses computer-numerical-controlled devices and the turret of numerous spindle and power-driven, sub-spindle lathes to perform several processes while the workpiece remains in alignment with the focal spindle.

Standard live tooling is most often suited to production work, where the finish, tolerances and cutter life are critical: whereas quick-change systems may be better suited to the shop producing familes of products and other instances where presetting the tool offline is a key factor in keeping the shop at maximum productivity. View Catalog Here

POTENTIAL APPLICATIONS OF LIVE TOOLING

Milling - Manufacturers can use live tools to eliminate materials from a revolving workpiece by progressing the tool into it. This happens by changing the working head speed and constantly changing direction on one or several axes.

Boring - You can use live tools to increase the size and diameter of an already drilled hole in a workpiece while ensuring precision.

Drilling - Live tools are used to drill cylindrical holes in workpieces held in a chuck, making it possible to connect or join machined parts or keep them in position.

Tapping - Live tools make it possible to cut threads inside a hole or slot on the material to allow the threading of screws into the hole.

Turning - Live tools ease turning processes where the material is cut from the external diameter of a rotating workpiece to lessen the workpiece to the specified or required diameter.

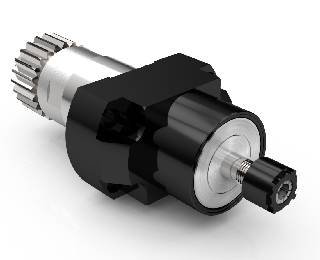

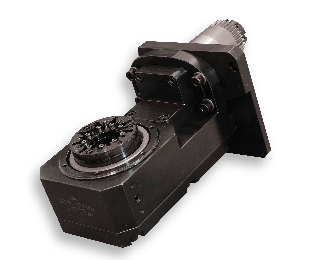

LIVE TOOLING ATTACHMENTS

GenSwiss offers high speed live tooling attachments with a maximum speed of 15,000 rpm. These attachments are available as a direct replacement for various Swiss machines with no retrofitting required. They provide increased speeds, feeds and tool life to reduce cycle times,

One of the benefits of buying live tooling and spindles from GenSwiss®, is knowing we will repair them too. We will repair your spindle at a fraction of the cost to purchase a brand new one and have your Swiss-style CNC running again in no time.

- $50 Evaluation And Inspection. The $50 inspection fee will be credited towards the cost of repair if the live tool is repaired.

- GenSwiss® repairs All PCM & OEM brands including: CITIZEN, STAR, TSUGAMI, & TORNOS.

- Repaired by factory trained professionals.

Please have the following info ready when contacting GenSwiss about your spindle:

- Model and serial number of your spindle

- Basic info on what is wrong with your spindle and the conditions in which it is running