WHAT IS THE CUT 3000 SYSTEM?

Rigid Swiss-type Machining

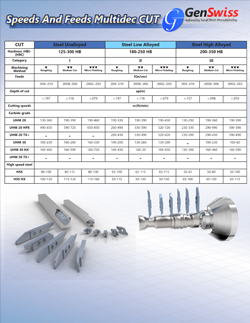

The multidec® turning and cut-off system for the Utilis® CUT 3000 Series is suitable for Swiss type lathes capable of machining bar stock with diameters between 10mm and 32mm. This series includes a large selection of cutting geometries with assorted chip breakers, specifically designed for small to medium sized parts manufacturing.

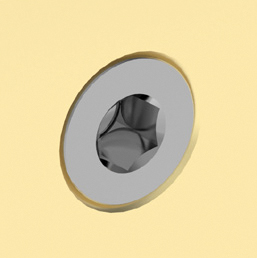

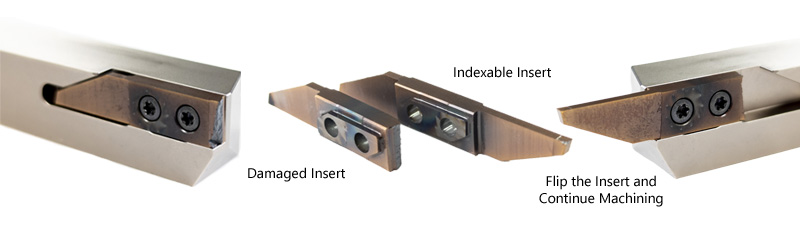

Indexable Inserts are designed to be easily mounted onto compatible tool holders, making them replaceable when the cutting edge becomes worn or damaged. Inserts are available in carbide grades of coated and uncoated ultra-fine grain substrates that can be utilized with various materials.

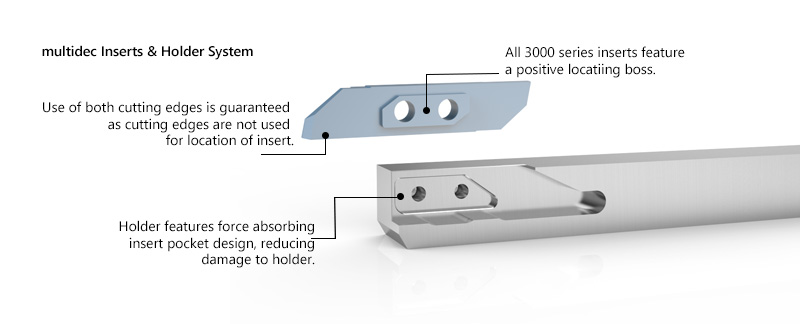

ADVANTAGES OF MULTIDEC®-CUT 3000 SERIES INSERTS & HOLDERS

• Indexable Inserts feature a Wide Variety of Chip Breaker Geometries

• All Inserts Fit the Same Holder

• Two Cutting Edges per Insert

• Cutting Edge Repeatable within .0004"

• Grooving Width up to 6mm

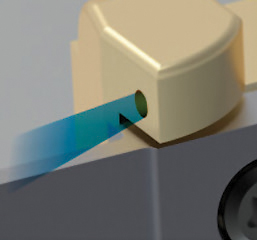

• Coolant Through Capability

• Improved Chip Control & Smaller Chip Volume

• Ideal for Large Feed Rates

VIDEOS

WHAT ARE THE BEST CASE USES FOR CUT 3000 SERIES INSERTS & HOLDERS?

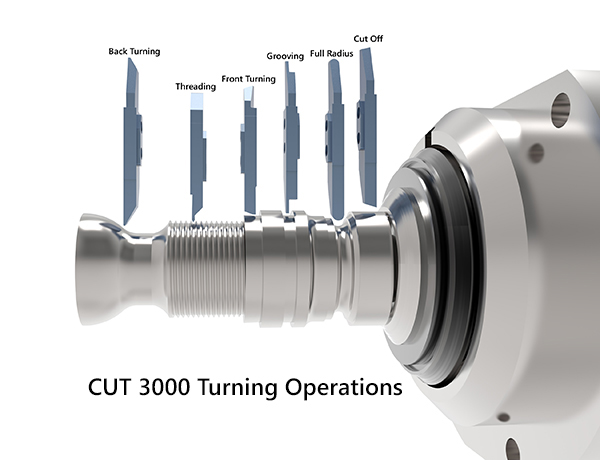

The grooving/turning tool systems of the Multidec-CUT 3000 Series are primarily used for external turning and internal turning.

Cutting edges with shank cross-sections from 7 to 25mm in length. Full profile threading inserts begin at 0.002 (0.06mm pitch) and grooving inserts' width start from 0.05mm suitable for large feed rates.

Ideal use for machining stainless steel and titanium in addition to machining of all common materials. The CUT 3000 inserts are available in ideally matched carbide grades of coated and uncoated ultra-fine grain substrates.

Multidec-CUT 3000 Holders with shank sizes between 8 and 25mm are available.

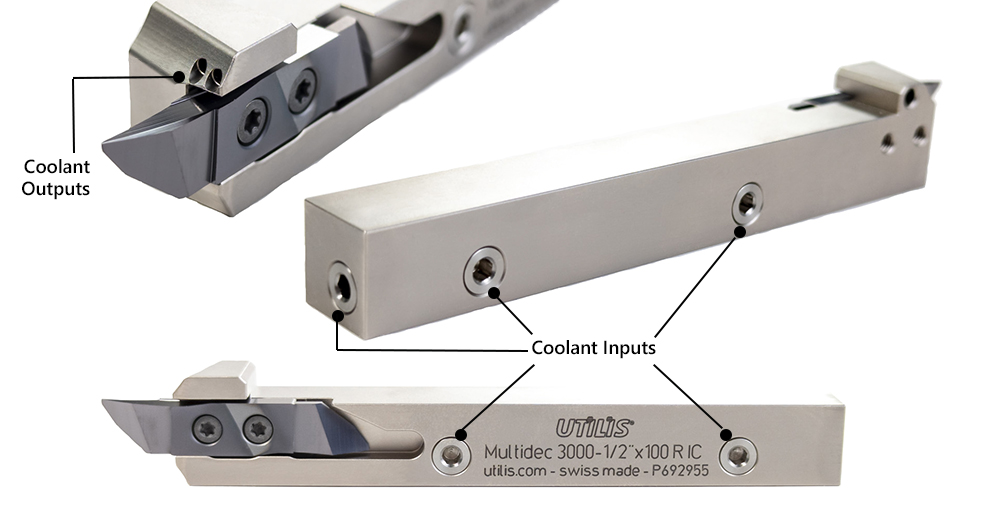

Multidec "IC" offers a wide range of coolant-thru holders featuring 5 connection ports for simple connection to your oil delivery system. Four side ports and one end port make connection possible on most machine tool positions.

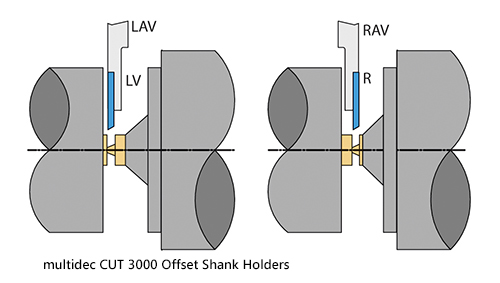

Offset Shank holders include clearances for extended nose guide bushings or for subspindle/pickoff clearance thus providing an ideal cutoff situation in tough applications.

Multidec SHORT coolant-thru holders enable the use of multidec turning inserts on commonly available quick change tooling systems.

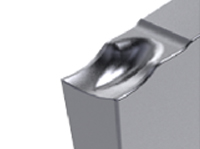

Use of the Chip Breakers

| Designation | Operation |

|---|---|

| 3002 | Part Cut-Off |

| 3003 | Front Turn |

| 3003 GA | Front Turn, Face, Back Turn |

| 3003 GM | Front Turn, Face, Back Turn & Copy Turn |

| 3004 | Back Turn |

| 3004 V SP | Copy Turn (Front |

| 3004 SP | Copy Turn (Back) |

| 3004 GB | Copy Turn (Back) |

| 3005 | Groove & Turn |

| 3006 | Thrading |

| 3007 | Full Radius Groove |

| 3012 | Chamfering |

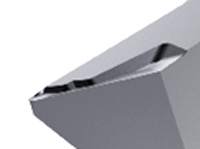

Geometry of 3000 Series Inserts

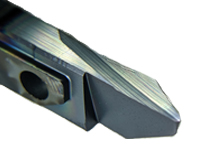

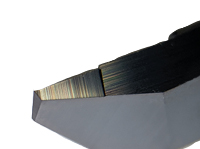

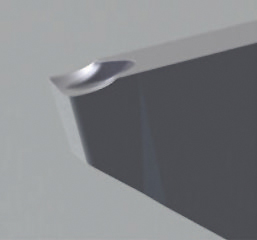

MULTIDEC® - CUT G-LINE INSERTS

With a focus on high productivity, process reliability, and the longest possible tool life, perfect chip control becomes a central issue in all modern production. These requirements are often difficult to fulfill with traditional ground chip breakers because of insufficient chip break and removal.

In comparison to traditional grinding technologies, new manufacturing technologies have increased the degree of design freedom tremendously, providing the ability to generate any three-dimensional shape. The new G-Line from multidec has adopted the use of this new free-form design technology, resulting in well thought-out chip breaking geometries that are fitted to the well-tried multidec -CUT 1600 and CUT 3000 series of turning inserts, providing maximum performance.

Freeform-modeled chip breakers achieve significant improvements in a wide range of materials when compared to ground chip breakers. This advantage is particularly evident with difficult to machine materials such as super-alloys. In addition to significantly improved chip control, multidec G-Line inserts can achieve up to 30% higher cutting values and up to 50% longer tool life.

ADVANTAGES OF MULTIDEC®-CUT, G-LINE INSERTS

• Improved Chip Control

• Better Cutting Values

• Longer Tool Life

• Smaller Chip Volume

• Better Process Reliability

• Wear-resistant and Tough Carbide Substrate with Two Heavy-duty Coatings

• Sharp and Rounded Cutting Edges

• Can be used on all Multidec-CUT 1600 and Multidec-CUT 3000 Holders

Execution of holder/insert

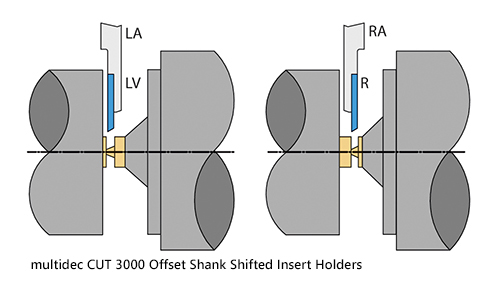

The side on which the insert is located determines whether it is a "left" or "right-hand" holder. For this purpose the holder is viewed with the insert pointing towards the observer.

The right-hand version of the tools is usually shown. (Exceptions are possible). For more information or to order G-Line products, please call 1-413-562-4800 or email [email protected]

MULTIDEC CUT3000 SERIES GLOSSARY TERMS

Chip Breaker: uses the drives of the machine to create an oscillation that produces small chips which are easier to remove, thus reducing machine downtime and ensuring continuous production.

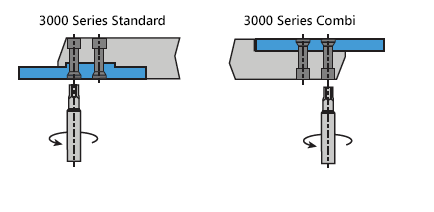

Combi Holder: Combi holders allow the insert fixing screws to be mounted from the opposite side of the holder using tapped bushings, making it easier to change the inserts.

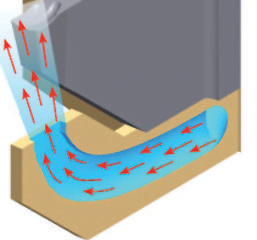

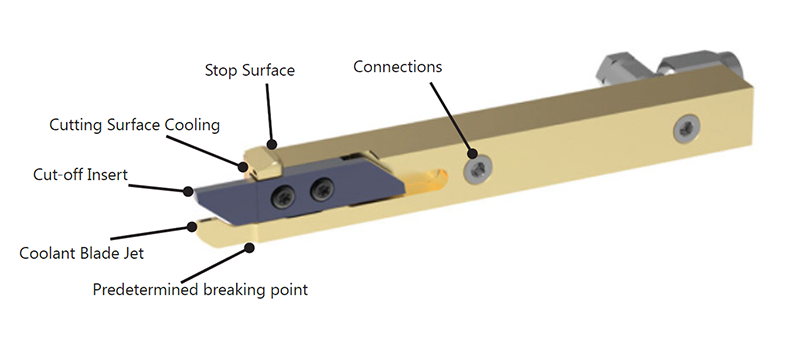

Coolant-thru Holder: holders with integrated coolant supply. Due to the high precision of the impact and the large pressure, the chip can be quickly and safely guided away from the cutting edge and the workpiece. This means a markedly longer tool life, coupled with high process reliability in series production.

G-Line Inserts: Freeform-modeled chip breakers achieve significant improvements in a wide range of materials in comparison to ground ones.

Gold Line Holder: The multidec Cut, Gold Line Holders provide a newly designed cooling system making it possible to double the lifetime of the cutting edges as well as increase the cutting parameters without having to accept higher wear.

IC: acronym attached to Utilis multidec holders with integrated (internal) cooling.

Indexable inserts: all indexable inserts are easily replaceable and are characterized by a very high repeatability. For the machining of all common materials, inserts are available in ideally matched carbide grades of coated and uncoated ultra-fine grain substrates.

Offset Shank & Insert Holder: the multidec shifted holders enable the cutting of short parts by enabling the cutting edge to move closer to the guide bushing therefore reducing the chance for deflection.

Offset Shank Holder: the multidec offset holders include clearance for extended nose guide bushings or for subspindle/pickoff clearance therefore providing an ideal cuttoff situation in tough applications.

Standard Holder: the basic multidec square shank tool holder for the CUT 3000 Series without internal coolant capability.

Short Holder: shorter holders that enable the use of multidec inserts on commonly available quick change tooling systems. All multidec Short holders feature internal cooling.

Utilis multidec®-CUT: the multidec range of indexable insert tools offer cutting-inserts and holders for internal and external turning, on swiss-type automatic lathes.

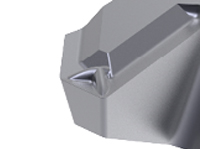

3000 STANDARD HOLDERS

Multidec standard holders are your basic square shank tool holder, a true Swiss-style holder where the cutting edge is flush with the mounting surface of the shank with no offset. These holders get your cutting insert right up on the guide bushing for maximum rigidity. Universal amongst all multidec holders, the insert pocket provides both clearance and protection for all CUT 3000 series geometries and chip breakers.

The recessed pockets of the multidec holder system is a great feature that prevents the loss of the mulditdec holder when wear or breakage occurs. For example, if you lose a cutting edge on the CUT 3000 insert or if part of the insert breaks off, you are able to index the insert around and utilize the other edge.

This type of pocket is the same across the whole CUT 3000 system and is compatible with all CUT 3000 series inserts, which includes geometries for cutoff, front-turning, back-turning, grooving, threading, and even full-radius grooving. Full-radius grooving is available "off the shelf" and is a special execution that is not readily offered by other tooling providers.

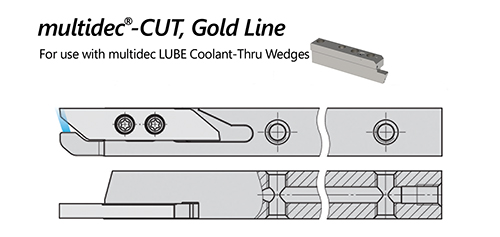

Shop HereMULTIDEC LUBE TOOL PLATES, WEDGES & ACCESSORIES

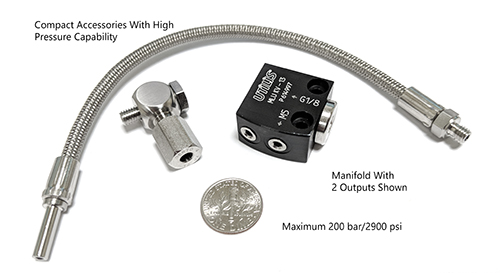

Accurate coolant delivery to the cutting edge is essential when machining modern materials for precision, but not all holders feature internal-cooling capability, which is the preferred method for delivering cutting lubrication. Standard holders offer high rigidity and repeatability, but they rely on external coolant hoses to deliver lubrication. Applying coolant as close to the cut as possible is important, and it can be difficult to limit space between the material and cutting insert without internal coolant capability. Don't worry, GenSwiss offers a multidec line of coolant-thru tooling wedges with an assortment of various quick change connectors, fittings, manifolds, and high-pressure coolant hoses sold in kits or separately à la carte.

View more information on multidec LUBE System (PDF)

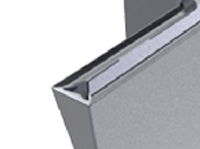

3000 COOLANT-THRU HOLDERS

We offer multidec 3000 Coolant-thru Tool Holders that feature an internal coolant jet stream aimed at the 3000 series insert edge. This is intended to provide optimal lubrication and cooling as well as longer insert life for front turning, back turning, grooving and threading operations. Similar to 16000 Series coolant-thru holders the 3000 Series contain multiple coolant-thru ports to accommodate your swiss type machine tooling positions.

Designed for pressures ranging to 2,000 PSI and offered in stock sizes of 1/2" and 5/8" square shank with other sizes available on request.

The multidec 3000 holders eliminate the use of solid coolant delivery lines, allowing for faster setup and more accurate coolant delivery position to the insert. There is no need for a custom proprietary gang plate, and no coolant manifold installation or other modifications to the coolant feed systems.

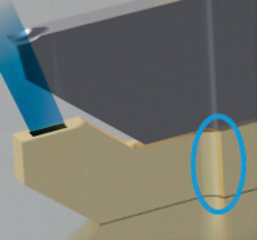

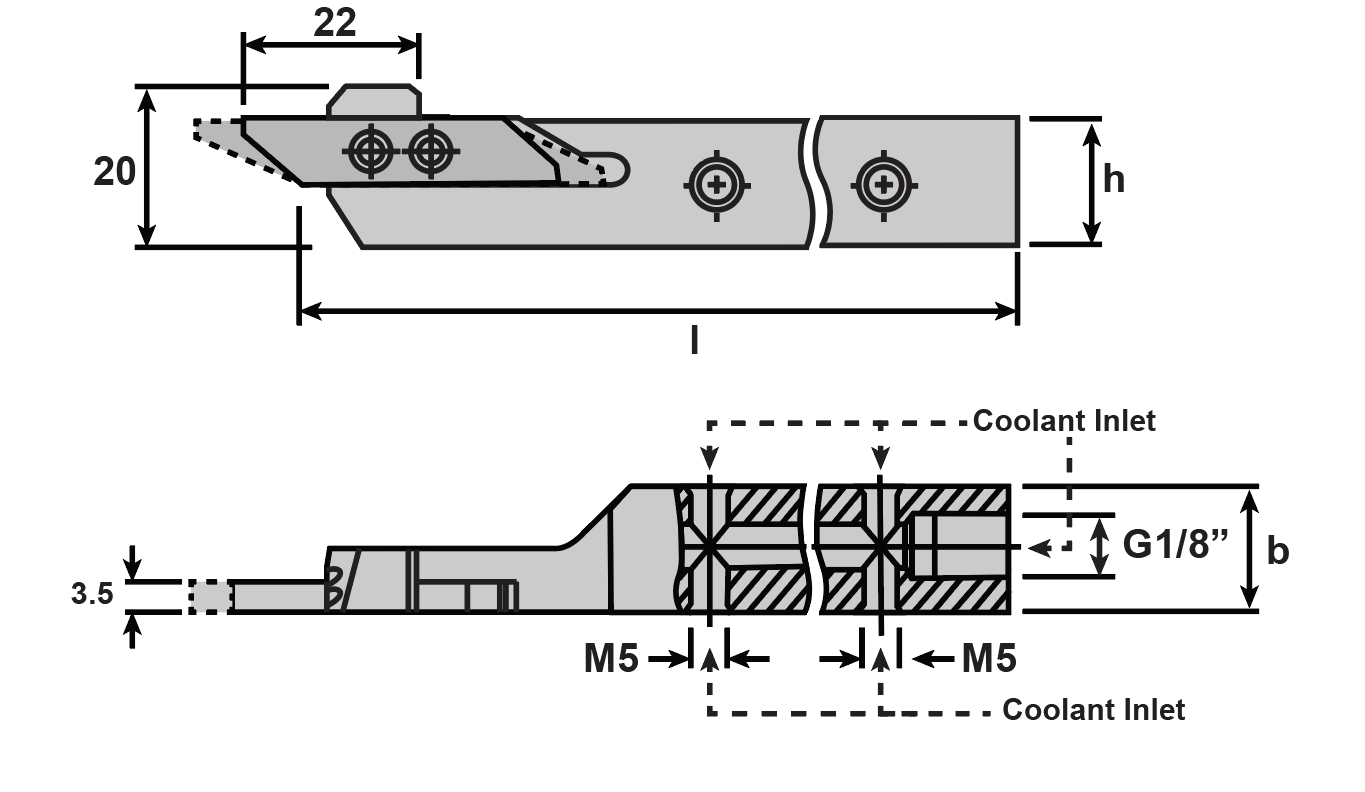

3000 OFFSET SHANK SHIFTED INSERT HOLDERS

Shifted holders enable the cutting of short parts by enabling the cutting edge to move closer to the guide bushing therefore reducing the chance of deflection. Available with or without coolant-thru system.

Shop Here

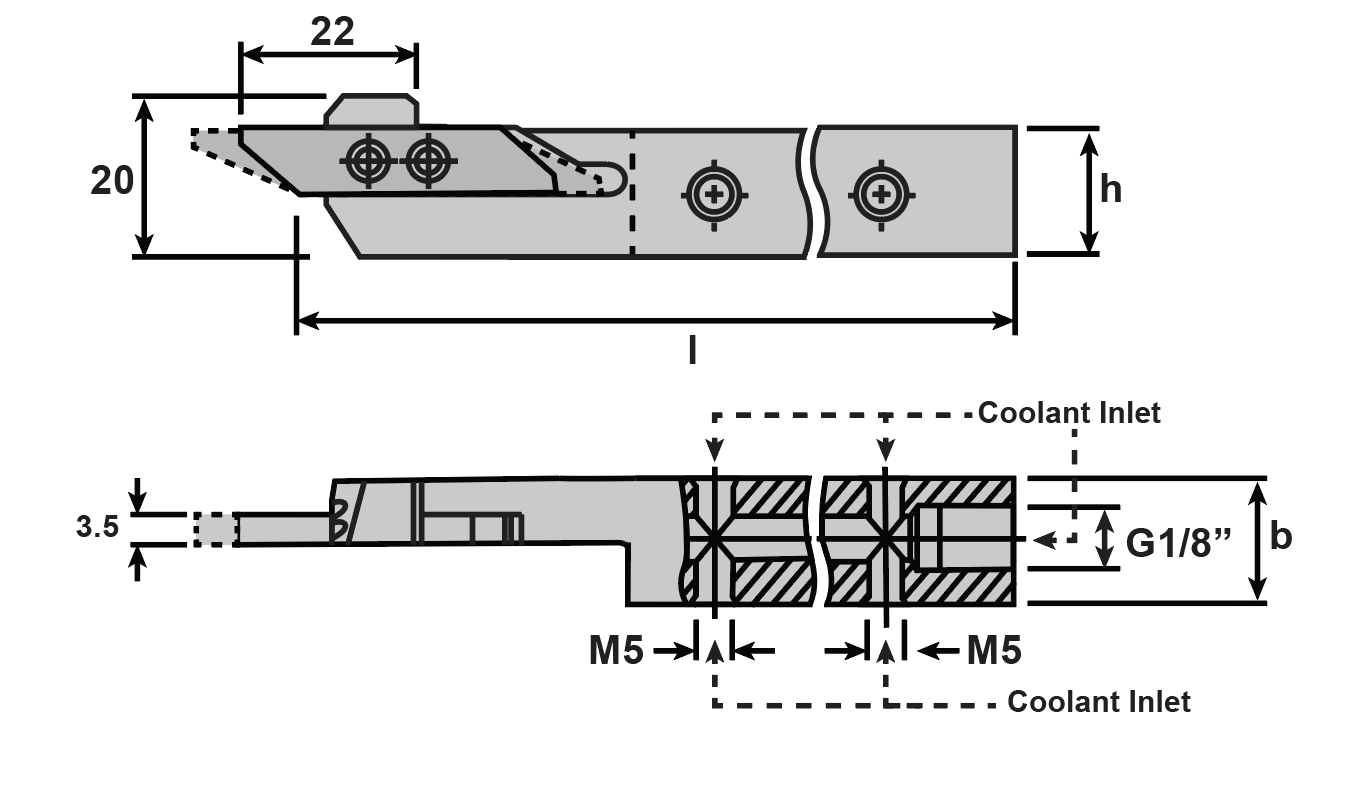

3000 OFFSET SHANK HOLDERS

Offset holders include clearances for extended nose guide bushings or for subspindle/pickoff clearance therefore providing an ideal cutoff situation in tough applications. Available with or without coolant-thru system.

Features five connection ports for simple connection to your oil delivery system: four side ports and one end port making connection possible on most machine tool positions.

Shop Here

3000 COMBI HOLDERS

3000 Series Combi holders allow the insert fixing screws to be mounted from the opposite side of the holder using tapped bushings, making it easier to change inserts.

Shop Here

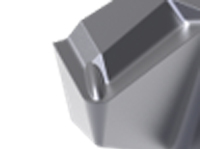

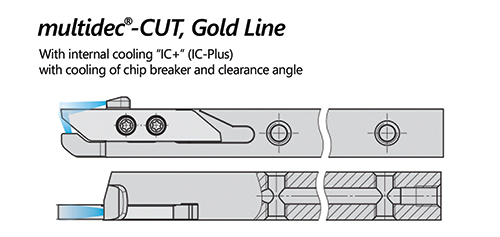

GOLD LINE HOLDERS

The multidec Cut, Gold Line tool holder was developed using a special manufacturing process with the goal of enabling even more efficient machining for cutoff and grooving on automatic lathes. The newly designed cooling system makes it possible to double the lifetime of the cutting edges as well as increase the cutting parameters without having to accept higher wear.

Two types are available. One "IC+" (IC-Plus) is equipped with chip breaker and clearance angle cooling.

The other type "IC-FK" is a version exclusively equipped with clearance angle cooling, which enables the combination with the innovative multidec-LUBE coolant-thru wedges.

Each of the tool holders are available for grooving inserts with a minimum width of 2mm.

ADVANTAGES

• 3D Coolant Holes with Optimized Clearance Angle Cooling

• Chip Breaker Cooling to Optimize Chip Control, Reduce Built-Up Edge and Improve Tool Life

• PVD Coating for Highest Wear and Corrosion Protection

GenSwiss is the exclusive dealer of the multidec® Cut, Gold Line tool holder available for the multidec® Cut, 3000 style inserts

SUCCESS STORY

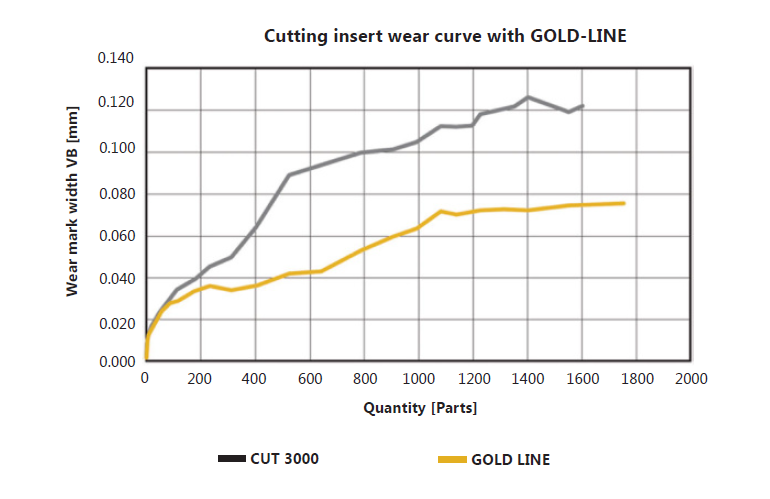

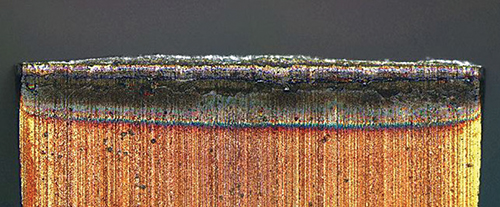

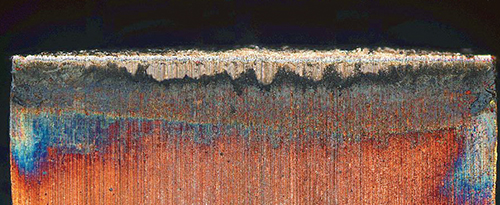

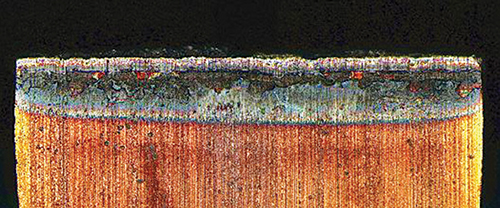

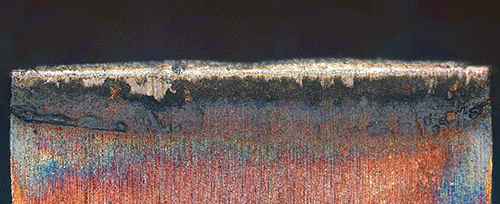

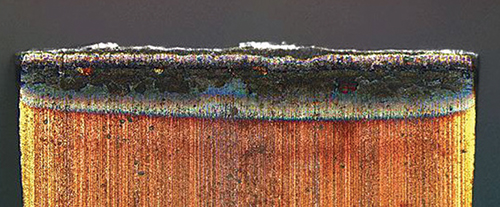

Starting situation - Tool life test

Two different holders were tested

– Reference product / conventional, but with cooling from the multidec® LUBE wedge on chip breaker.

– 3000- 12-100 (GOLD LINE IC+) with cooling from holder to chip breaker and clearance angle.

A 3002-2.0-10 LN SPT06 UHM20 TX+ was used for parting off.

Testing took place in accordance with the "Standardized testing process" R&D (research & development).

Type of machine: Star SR20

Material No.: 1.4435 (316L), stainless steel

Diameter: 12 mm

Operation: Parting off

Coolant: Oil

Cutting speed: (Vc) 120m/min

Feed (f): 0.04mm /U

multidec - CUT, GOLD LINE vs. Reference product/conventional

Number of parts 525 GOLD LINE  vs. Reference product/conventional

vs. Reference product/conventional

Number of parts 1080 GOLD LINE  vs. Reference product/conventional

vs. Reference product/conventional

Number of parts 1600 GOLD LINE  vs. Reference product/conventional

vs. Reference product/conventional

Performance Comparison

The line diagram shows the development of the free face wear on the basis of the test result. The quantity (parts) was shown for illustration purposes.