WHAT IS MULTIDEC LUBE?

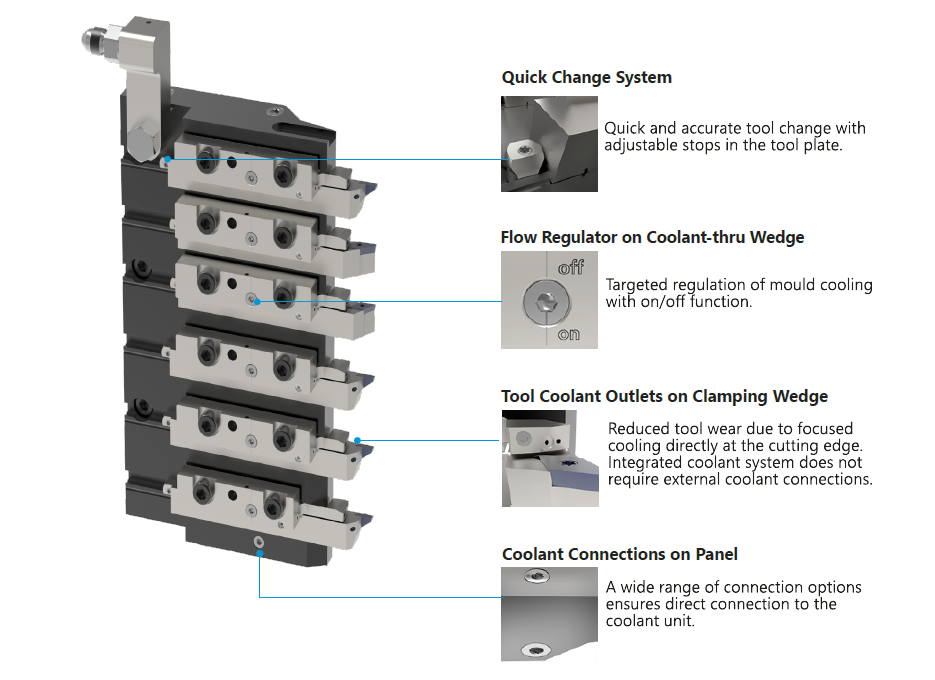

Tool Plates with Integrated Coolant

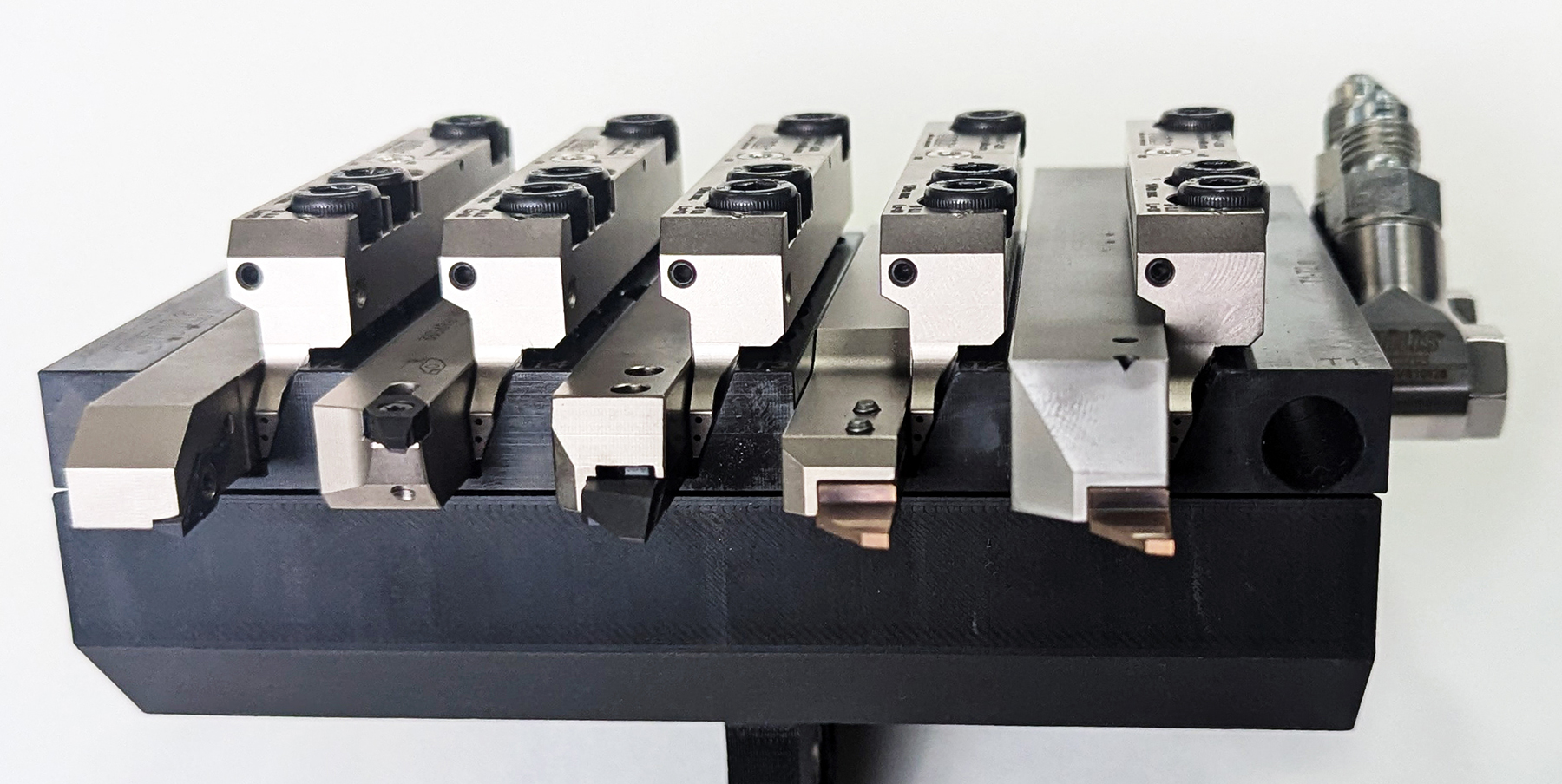

Introducing the compact quick-change multidec®LUBE tool plate system designed to increase the efficiency and process reliability of your sliding headstock machine. This revolutionary design provides one coolant connection to the entire tooling plate which eliminates the lubricant distributor and connecting hoses. The complete package includes tool plate, clamping shim with coolant control screw, tool stops, torque screwdriver and mounting screws.

Advantages

• Easily install any original plate with the complete multidec LUBE tool plate

• Use your existing inserts and holder to retrofit your existing tool-plate

• Quick and safe replacement of inserts with integrated stop

• Tool holders without internal cooling (IC) can continue to be used

• Allows for pre-setting of tool lengths

• Made for temperature range of –60 to +250 °C or –76 to +482 °F

• Up to a Maximum operating pressure of 200 bar or 2,900 psi

• Various coolant distributors, hoses and push-in fittings for high and low pressure are available View Here

WHAT ARE THE BEST CASE USES FOR MULTIDEC LUBE?

Multidec LUBE offers the ability to do a one-time setup of coolant, saving you time on setups while increasing process reliability and machine run-time. You’re not going to have to worry about bending lines anymore or directing cooling jets because that is all part of this integrated system.

The multidec plate takes it one step further. Now we’ve got the ability to add very repeatable quick change built into the plate and you don’t have to use special shanks that go with it.

Coolant Jets are all built into the wedges. So not only are you establishing the coolant connection once (through the main left side), you don’t have to touch it again because it runs through the plate itself and delivers coolant through the individual wedges.

Dovetail keyways are all set with positive stops. These are all adjustable so you can have your setup guy establish all the stops and then you can have your operator run production.

Available for Tornos Nano, Citizen, Star, Tsugami. We can work to customize this for other machines as well. Call GenSwiss for more information 413-562-4800

Multidec LUBE - Two Options Available

1) The first option is a complete tool system, consisting of a tool plate and wedges, in which the lubricant is directed through the tool plate directly onto the cutting edge via the coolant-thru wedge.

Pictured above (non-coolant insert holders)

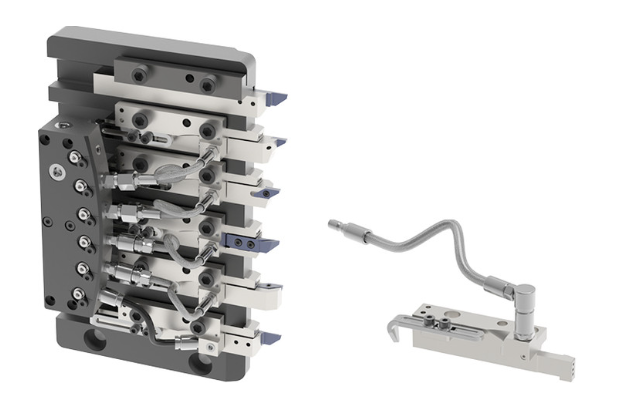

2) The second option is to replace the existing original wedges on your original tool plate with multidec LUBE wedges, which also direct the lubricant directly to the cutting edge. With the second option, you keep your original tooling plate and simply replace the wedges with the multidec LUBE models and connect them to your lubricant dispenser.

In our multidec LUBE program, a wide range of accessories are available for high and low pressure; lubricant distributors, hoses, screw connections and quick-connect couplings. The great advantage of the UTILIS multidec LUBE system is that you are completely independent and can use your existing inserts and insert holders.

Take advantage of these benefits and increase the performance of your machine.

Multidec LUBE Coolant-Thru Wedges for existing original tool plates (Option 2)

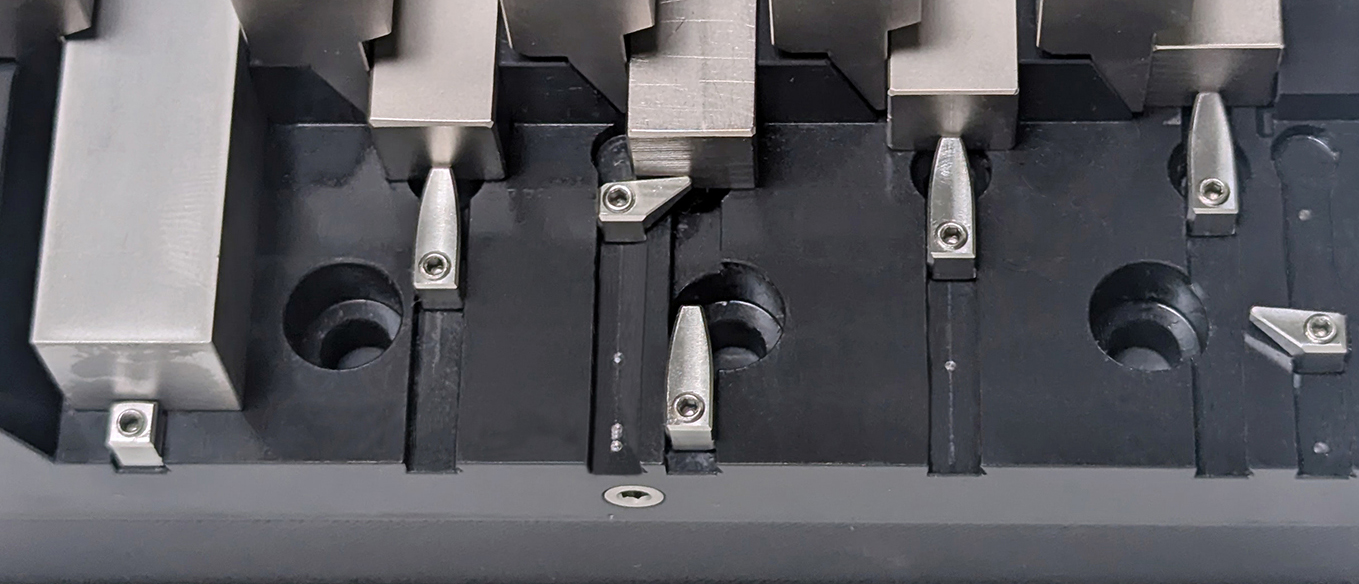

The Multidec-LUBE Coolant-Thru Tool Holder Wedges incorporates a coolant/oil delivery passage in the tool clamp that ensures a repeatable jet flow even after multiple tool changes or setups. This feature allows use of conventional square shank tool holders as if they were coolant-thru since the coolant travels through the clamp and can remain semi-permanently plumbed into the high-pressure system

The corrosion-resistant, low-profile system offers straight and swivel-type connections in a variety of lengths, and features quick-release fittings, eliminating the need for unscrewing and thus reducing downtime. The high-pressure coolant tubes can be connected directly with LUB shims of IC holders eliminating the need to route high-pressure lines from setup-to-setup. The coolant distributor housing is designed with two to eight outlets to suit a range of machining cycles for simple and complex parts production requirements. For high-pressure coolant operation, the steel components are built to withstand pressures as high as 2,900 psi.

The patented design incorporates a coolant/oil delivery passage in the tool clamp ensuring a repeatable jet flow even after multiple tool changes or setups or teardown and replaces the original equipment gang slide tool clamps provided with the Swiss machine.

This feature also allows use of conventional square shank tool holders as if they were coolant-thru since the coolant travels through the clamp and can remain semi-permanently plumbed into the high-pressure system. The clamp is designed to work with square tool holder shanks and allows for an easy fit into the machine, plus gaining greater rigidity when compared to other quick-change coolant-thru tooling available to the industry.

In addition, a fixed and adjustable stop makes it possible to position the tools in exactly the same location following insert changes ensuring high repeatability. Typical problems solved include elimination of stringy chip wraparounds or clogging, avoiding accidental bending or repositioning of coolant tubes/nozzles with subsequent tool changes over machining cycles, resulting in time savings while achieving measurable machining efficiencies.

Tool Plate Inquiry?

Are you interested in multidec LUBE complete tool plates or coolant-thru wedges? If so, please contact us today at 413-562-4800 or send us an inquiry [email protected] with the CAD data of the original tool plate or provide us with the original tool plate for measuring. Our technical team of experts provide quick response and most custom orders are available.